As the central controller in motion control and position feedback systems, encoder performance directly impacts control accuracy, system stability, and operating efficiency. Achieving higher encoder performance ultimately depends on advancements in the MCU that performs core control and signal processing.

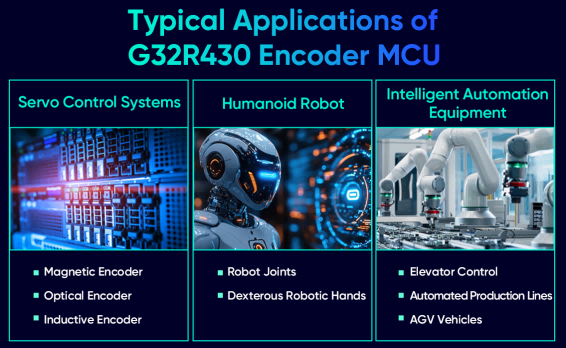

Conventional general-purpose MCUs often fail to meet the demanding requirements of next-generation encoders. To address this gap, Geehy introduces its first dedicated encoder MCU, the G32R430. Designed specifically for magnetic, optical, and inductive encoders, the G32R430 delivers substantial improvements in accuracy, power efficiency, and real-time performance through optimized system architecture and peripheral integration.

High Energy Efficiency and Low-Latency Processing Performance

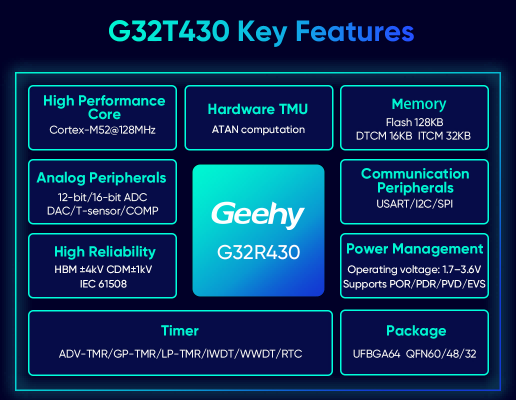

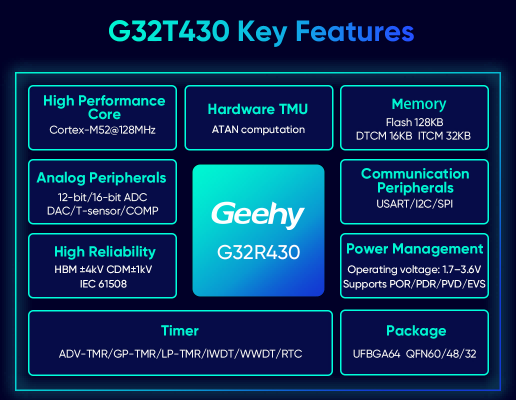

The G32R430 is based on the Arm® v8.1-M architecture and integrates a next-generation Cortex®-M52 core operating at up to 128MHz. It supports ITCM and DTCM tightly coupled memory for zero-wait-state instruction and data access. Together with a 4KB high-speed cache, this architecture significantly improves execution efficiency, ensuring ultra-low-latency processing of position signals and reliable support for high-precision motion control.

Proprietary ATAN Instruction for Microsecond-Level Angle Computation

The G32R430 integrates a hardware TMU and supports Geehy’s proprietary ATAN electrical-angle computation instruction. By accelerating trigonometric calculations in hardware, it achieves ATAN accuracy better than 0.0001° and electrical angle output latency below 1μs. This enables precise detection of minute angle changes, improves position feedback speed by approximately 40%, and enhances real-time responsiveness and control loop performance in servo systems.

High-Sensitivity Signal Acquisition

The MCU integrates two 16-bit high-precision ADCs supporting regular, injected, single-shot, and continuous sampling modes. Master–slave configuration enables synchronous multi-channel sampling. Both differential and single-ended inputs are supported, with an effective resolution of 13.5 bits in differential mode, further extendable through oversampling. The G32R430 reliably supports magnetic encoders with ≥17-bit resolution and optical encoders with ≥23-bit resolution, ensuring high signal accuracy from the acquisition stage.

High Integration for Simplified System Design

By integrating key analog, digital, and power management functions on-chip, the G32R430 significantly simplifies system design and reduces BOM cost.

• 1 × 12-bit ADC supporting up to 14 external channels and 2 internal channels for multi-channel signal acquisition.

• 2 × 10-bit DACs configurable as comparator inputs for flexible signal processing.

• 4 × programmable analog comparators for zero-crossing detection and window comparison.

• 1 × high-precision temperature sensor for temperature compensation and measurement stability.

• Main supply voltage sensing (EVS) for accurate power-on and power-down detection without external circuitry, reducing PCB size and overall BOM cost.

The MCU also integrates multiple high-speed communication interfaces to enable reliable data exchange with servo drives, PLCs, and industrial controllers.

• 2 × USARTs with data rates up to 16Msps and automatic RS485 transmit-enable control.

• 1 × I²C interface supporting up to 400kHz.

• 1 × SPI interface supporting master/slave modes with data rates up to 50 Mbit/s.

• Support for Tamagawa, BiSS-C, SSI, SPI, and other mainstream encoder protocols.

This high level of integration improves system reliability, optimizes hardware utilization, and supports compact, high-performance encoder and control designs.

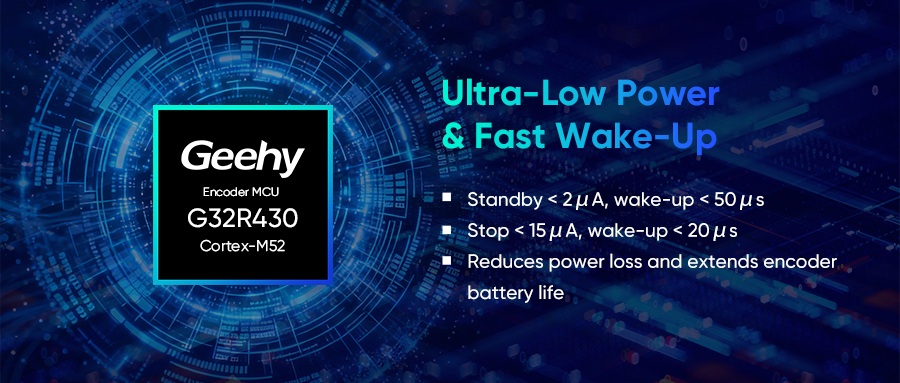

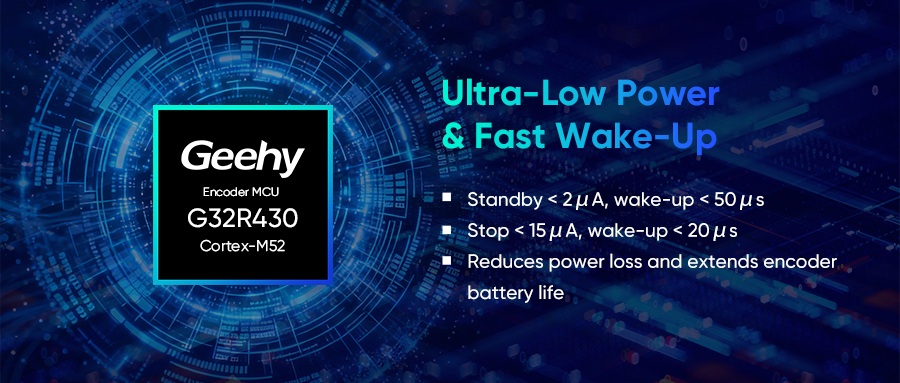

Ultra-Low-Power Design for Enhanced Energy Efficiency

The G32R430 supports Stop and Standby low-power modes. In Stop mode, power consumption is below 15μA with wake-up time under 20μs; in Standby mode, power consumption is below 2μA with wake-up time under 50μs. These features significantly extend battery life in portable or battery-powered encoders. Fast wake-up enables seamless resumption of real-time control tasks, reducing overall encoder power consumption by approximately 50% compared with traditional solutions.

The MCU operates over a wide supply voltage range of 1.7V to 3.6V and a temperature range of –40°C to +105°C. It complies with IEC 61508 industrial standards, offers strong ESD protection (HBM 4kV / CDM 1kV), and supports power-on reset, power-down reset, and a programmable voltage detector. The G32R430 series is available in UFBGA64, QFN60, QFN48, and QFN32 packages to support diverse application needs.

Comprehensive Ecosystem Support to Accelerate Product Deployment

The G32R430 is backed by a complete development ecosystem, including datasheets, user manuals, and application notes. Geehy provides SDKs, TinyBoard development boards, and magnetic absolute encoder reference designs, with support for mainstream IDEs such as Keil and IAR. From concept to mass production, Geehy offers end-to-end support to help engineers accelerate development and shorten time to market. Samples are now available through local Geehy sales offices.

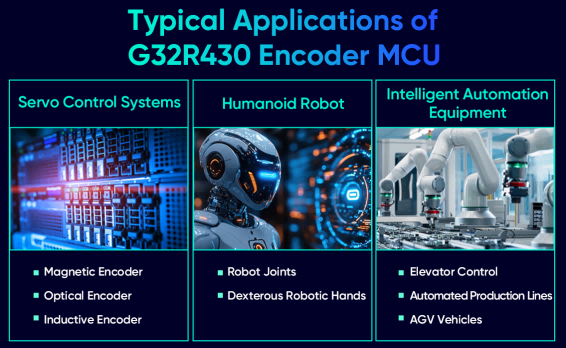

The G32R430 is well-suited for servo systems, embodied robotics, and intelligent automation equipment.

Following the G32R501 real-time MCU/DSP, the G32R430 marks another key milestone in Geehy’s “Industrial MCU+” strategy. Geehy has established a full-stack industrial chip platform covering “control + sensing + drive.” Looking forward, Geehy will continue to strengthen its core technology and market competitiveness in industrial MCUs, enabling industrial automation, embodied robotics, smart energy, new energy vehicles, and emerging low-altitude economy applications, while addressing critical bottlenecks and advancing the development of high-end industrial semiconductors.