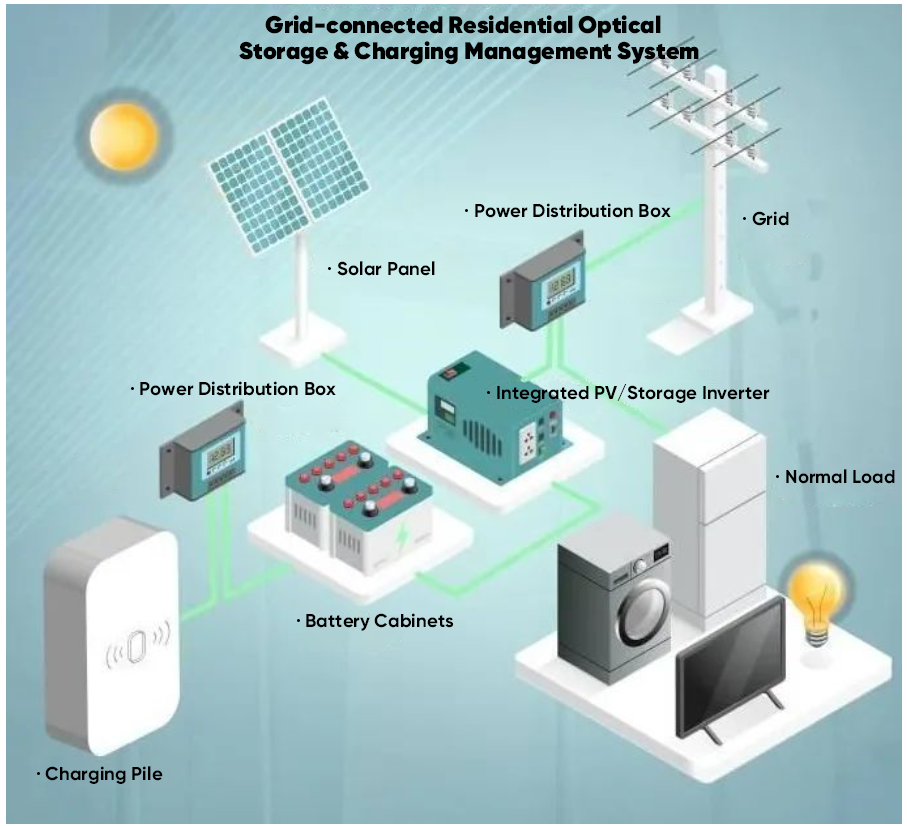

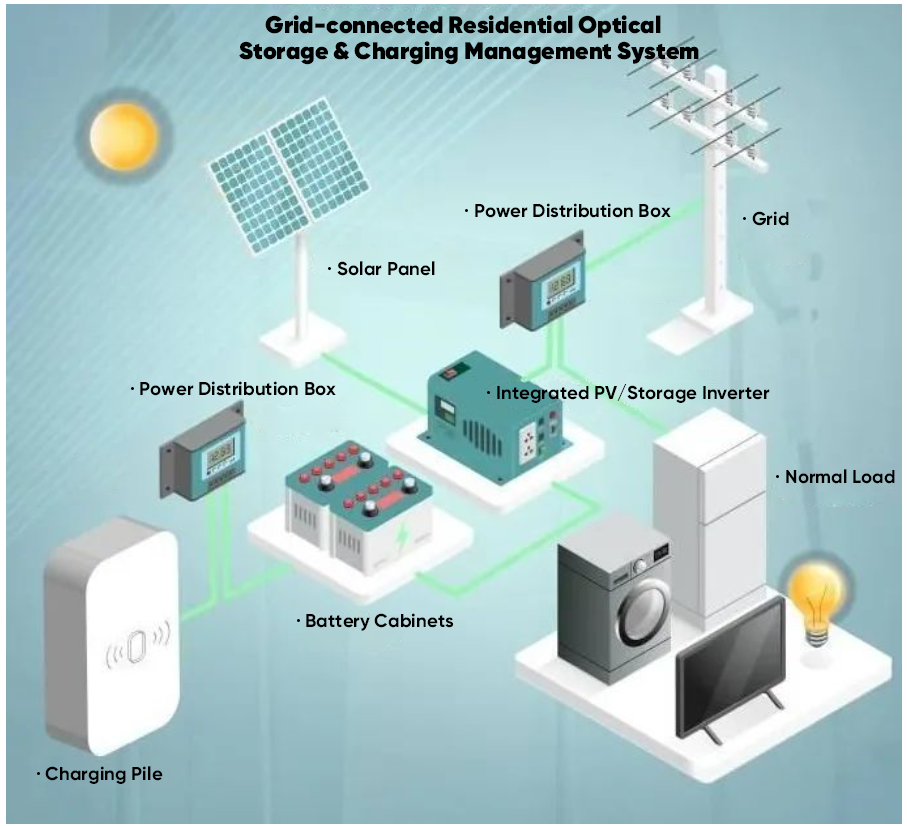

The popular grid-connected residential optical storage & charging management system in the new energy field effectively combines a PV system, a power storage system, a normal load part, and a charging pile, which helps to save electricity expenses, expand the proportion of green electricity consumption, reduce the impact of urban power supply, and guarantee the safety and stability of electricity consumption.

Grid-connected Residential Optical Storage & Charging Management System

Currently, the industrial-grade APM32 MCUs have been successfully used in micro PV inverters, DC charging piles, and energy storage solutions.

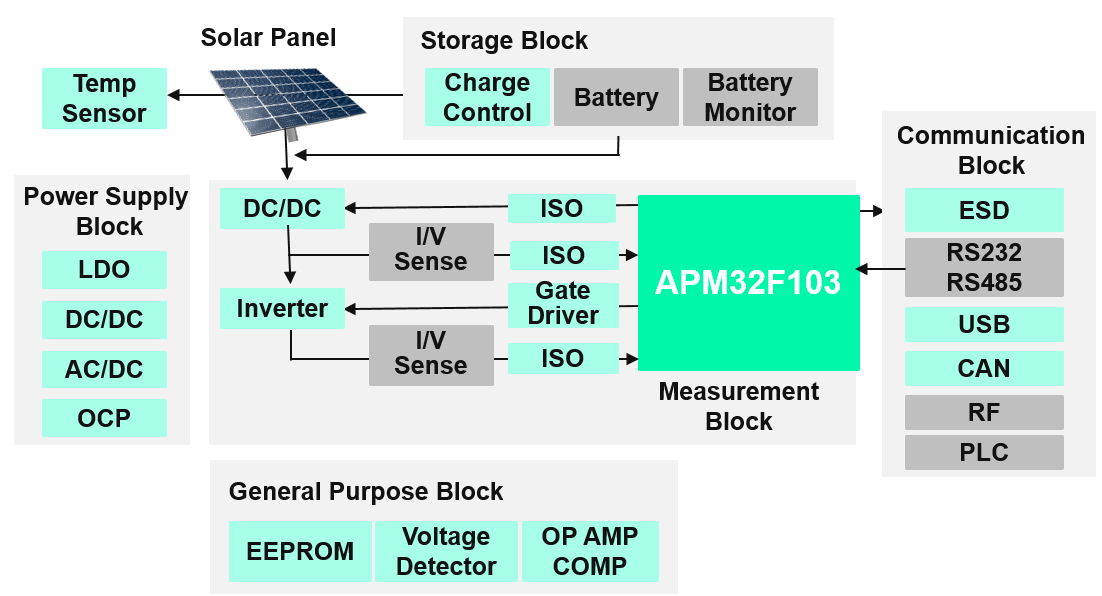

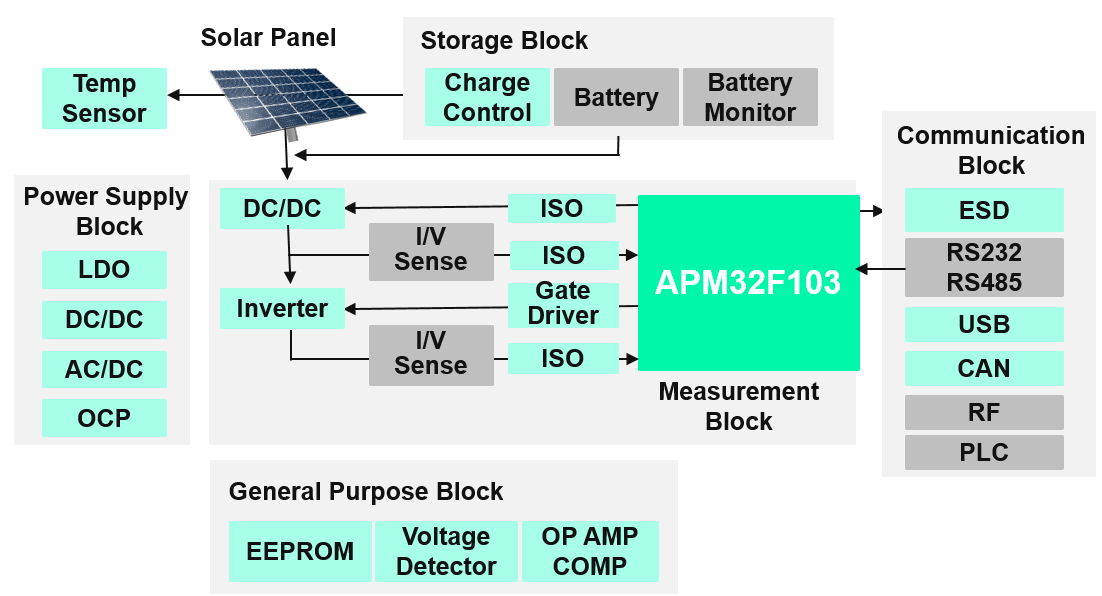

APM32 Micro PV Inverter Solution

Based on the APM32F103 MCU series, the micro PV inverter operates at a frequency of 120MHz, 512KB Flash, and 128KB SRAM, suitable for 0~500W and 18V~36V solar panels, which can provide high-performance computing, simplify the product design and help the grid to achieve robustness and reliability.

Features:

• Supports power management, boost inverter boost, and AC220V output control

• Maximum input power is 500W, maximum instantaneous output power is 1000W

• Supports overtemperature, under voltage, output overload, overcurrent, output short circuit, and other protection functions

• Supports online upgrades, mobile APP monitoring, and other functions

APM32 Micro PV Inverter Solution

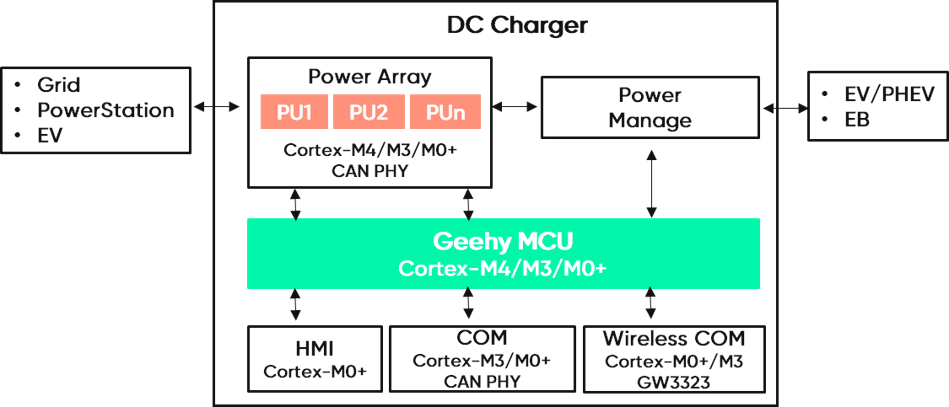

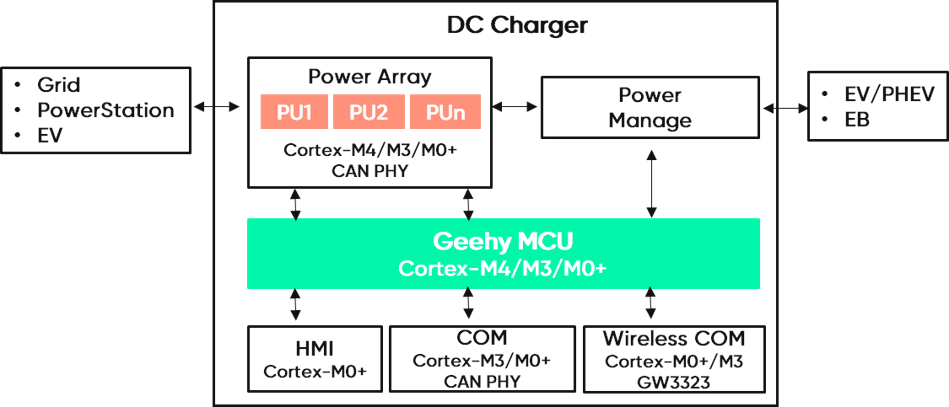

With the characteristics of low power consumption, high performance, high integration, and high stability, the industrial-grade APM32 MCUs have been fully applied in charging management and data communication of mainstream charging piles.

The DC charging pile system mainly consists of three parts: a power unit, general control unit, and HMI. Based on the APM32F4 high-performance MCUs (Cortex-M4), the DC charging pile solution realizes power AC/DC inverter in the power unit, and the general control unit completes the power management, charging management, and data processing, which can realize the main functions of DC charging piles such as national DC charger identification, electronic lock control, 12V/24V power identification and output, vehicle CAN communication and background data transmission. HMI, as the human-machine interface of the DC charging pile, can realize charging operation and key data display of vehicle and pile, which is mainly powered by the industrial-grade APM32F1 series (Cortex-M3), APM32F0 series (Cortex-M3), and APM32F0 series.

The APM32F405/407 MC series is based on Arm® Cortex®-M4 core with a frequency of 168MHz, which fully takes into account the characteristics of high computing, high real-time, and ease of use. It has excellent CPU computing performance, and supports single-precision FPU and enhanced DSP. The 1MB Flash, 192+4KB SRAM, optional SDRM 2MB, and rich peripheral meet the data computing and storage requirements of charging piles. Moreover, the APM32F405/407 series supports a high-speed OTG unit with on-chip PHY, 100G Ethernet MAC, and other rich peripherals, which are suitable for the design of small and medium-sized charging piles.

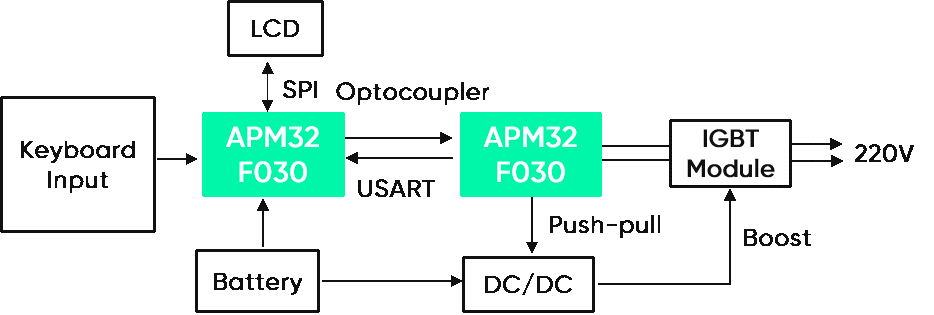

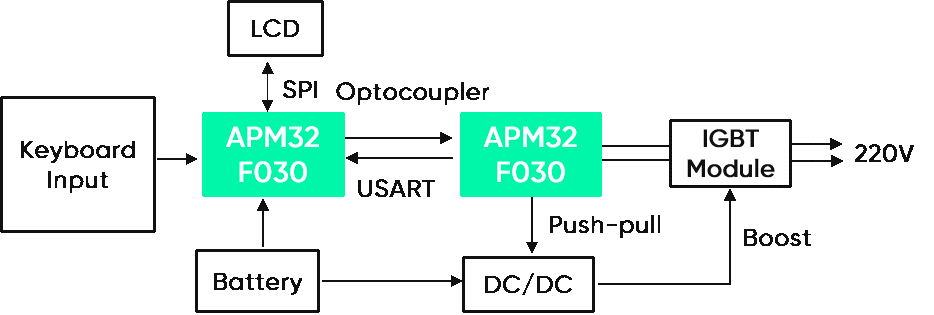

APM32 Micro PV Inverter Solution

Based on the industrial-grade APM32F030 MCU series, the energy storage solution operates at a frequency of 48MHz, 32~256KB Flash, and 4~32KB SRAM. It meets the features and functions required for energy storage and is cost-effective to help end-users meet the challenges of designing power supplies with higher energy efficiency, smaller size, and better heat dissipation.

Features:

• Output Output voltage: 220V±2%, output frequency: 50Hz±0.1Hz, rated output current: 2.3A

• Supports DC bus voltage, over voltage and under voltage protection, output overload, overcurrent protection, PCB/IGBT overtemperature protection, and output short circuit protection

• Power management: Realize input and output control. Complete relevant commands through I/O buttons and realize charging management by identifying input power conditions.

• Power conversion: The push-pull circuit DC/DC boost converter and DC/AC converter are controlled by PWM, while the ADC is used to detect the voltage to form a closed-loop feedback.

• Data management and status display: With the functions of real-time data processing, including battery SOC estimation, input and output power, and system status. The communication interface communicates with the LCD screen to realize the system status display.