The surge in outdoor activities such as tourism, camping, and self-driving tours has significantly increased the demand for portable electrical devices. This trend is driving the growth of the portable power station market, which is projected to reach $1.087 billion globally by 2029, according to Zhongyan Research.

Advancements in technology have raised consumer expectations for portable power stations. Beyond basic needs like storage capacity, safety, and portability, consumers now seek products that are aesthetically appealing, multifunctional, and user-friendly. This new solution meets these demands by using the highly adaptable industrial-grade APM32F411RET6 MCU as the main control chip, offering an optimal balance of performance, functionality, and size for creating cost-effective and competitive portable power stations.

Features of the APM32F411-Based Control Board Solution for Portable Power Station

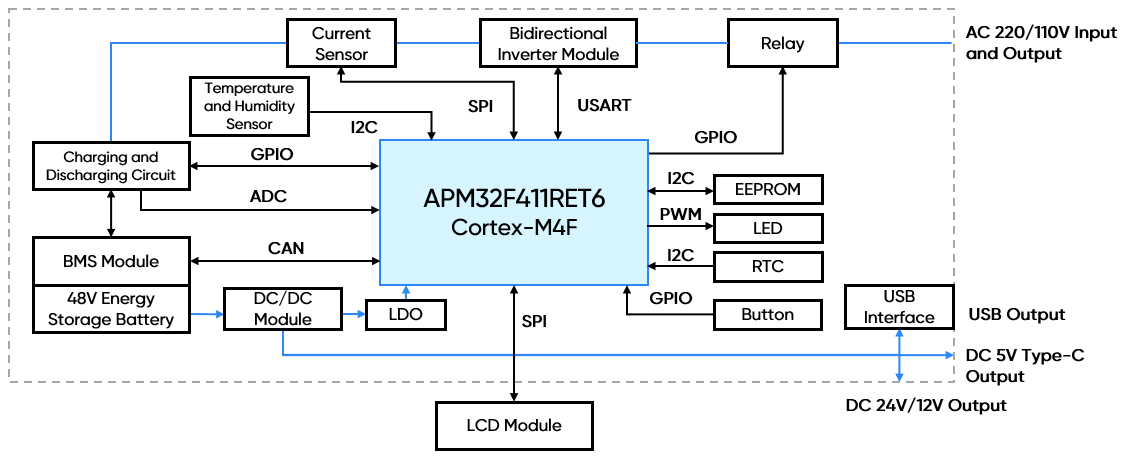

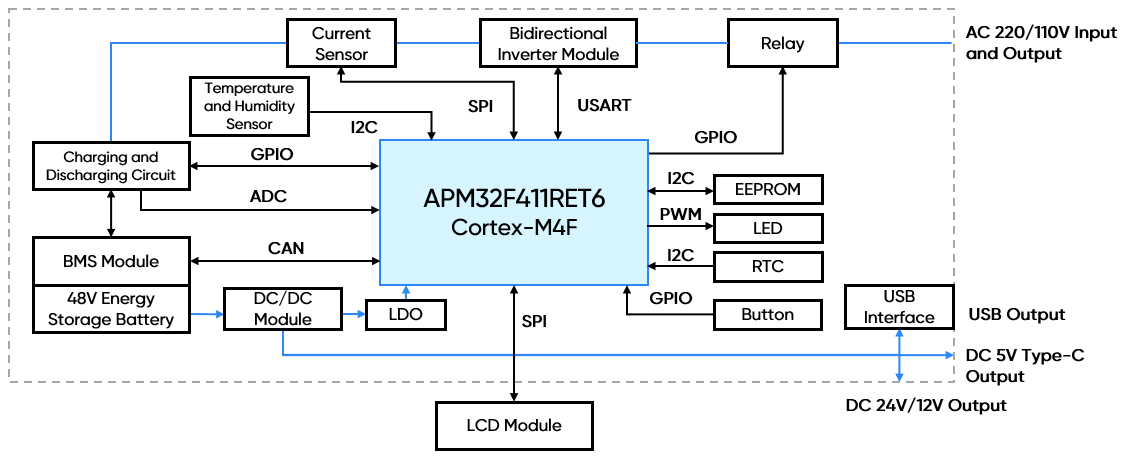

This solution features a 3.6KW portable power station control board with lithium iron phosphate battery cells and an integrated bidirectional inverter module. Despite its compact size and high power density, it supports 220V input and output along with dual-mode charging and discharging capabilities. Key features include:

Multi-Mode Stable Charging and Discharging

· Maximum battery capacity: 2048Wh, cycle count: 4000 times

· Charging modes: 220–240V AC, 500W car charging, and 1000W maximum solar panel charging

· Output modes: 220V/2400W, 220–240V AC output, and maximum 10A

· USB output: USB-A up to 18W, Type-C up to 100W

· Car charger output: 12.6V/126W, DC5521 up to 12.6V/38W

User-Friendly and Multi-Function Design

· Supports human-machine interaction with an external LCD module via SPI interface to display current power, remaining working time, charging and discharging status, time, real-time temperature and humidity, fault alarms, and scheduled output information.

· Features button input for setting discharge mode, over-power output mode, timer duration, alarm thresholds, password protection, child lock, Bluetooth connection, and more.

· Includes built-in EEPROM to save system settings and user habitual working modes.

· Integrates a temperature and humidity sensor and a high-precision RTC chip for accurate temperature and humidity information and time communication with the MCU.

· Supports Bluetooth connectivity, allowing users to interact with the device using a mobile app.

· Enables LED control via mobile app or buttons for turning on/off and adjusting brightness.

· Utilizes an MCU with a built-in CAN controller for BMS communication to obtain EMS real-time status and battery data.

Robust Safety Protection Mechanisms

· Incorporates the APM32F411RET6 MCU to control the bidirectional inverter through algorithms, enabling charging and discharging, automatically detecting real-time current and voltage conditions, ensuring normal operation, and initiating protection mechanisms via relay cutoff in case of faults.

· Employs a current sensor chip for line current detection, with the MCU adjusting the working state through sensor feedback for system protection and power regulation.

· Provides protections against over-discharge, overcharge, undervoltage, overload, static electricity, high and low temperatures, external short circuits, voltage difference, and circuit interruption for electrical safety.

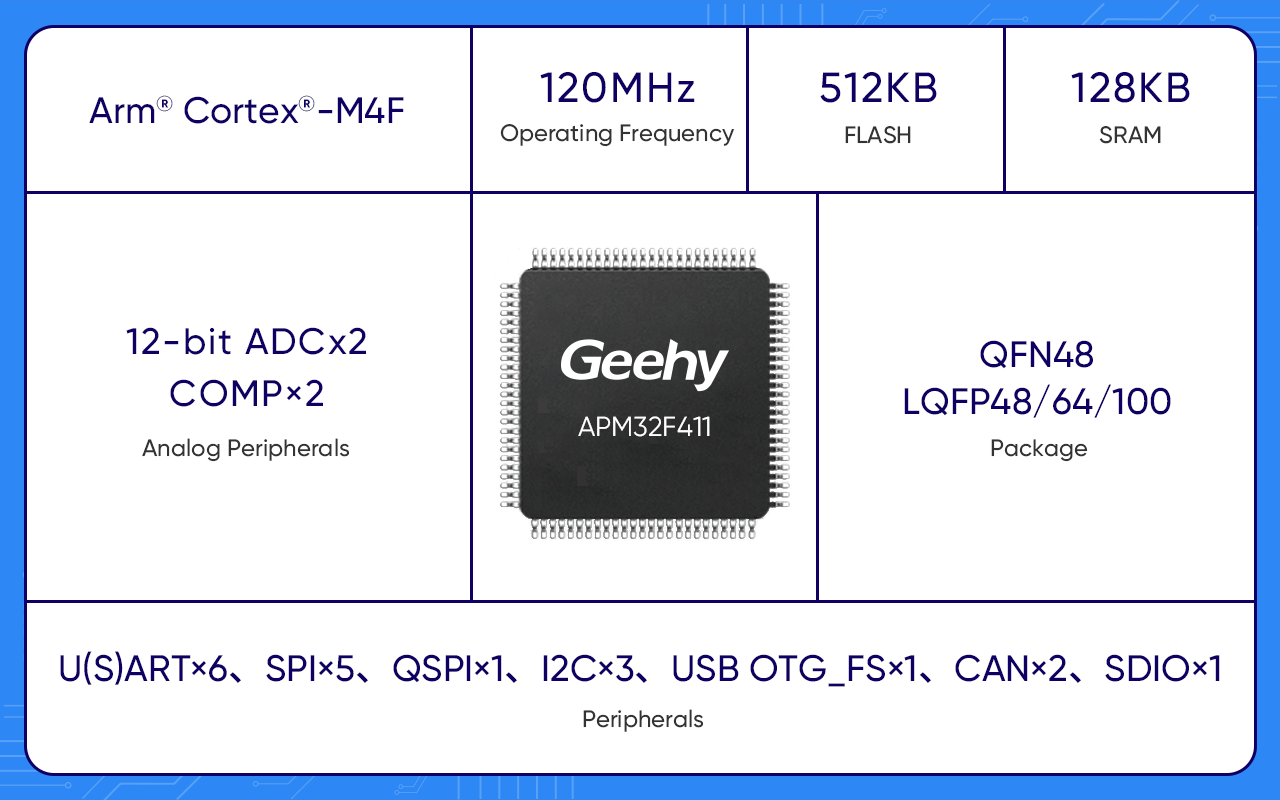

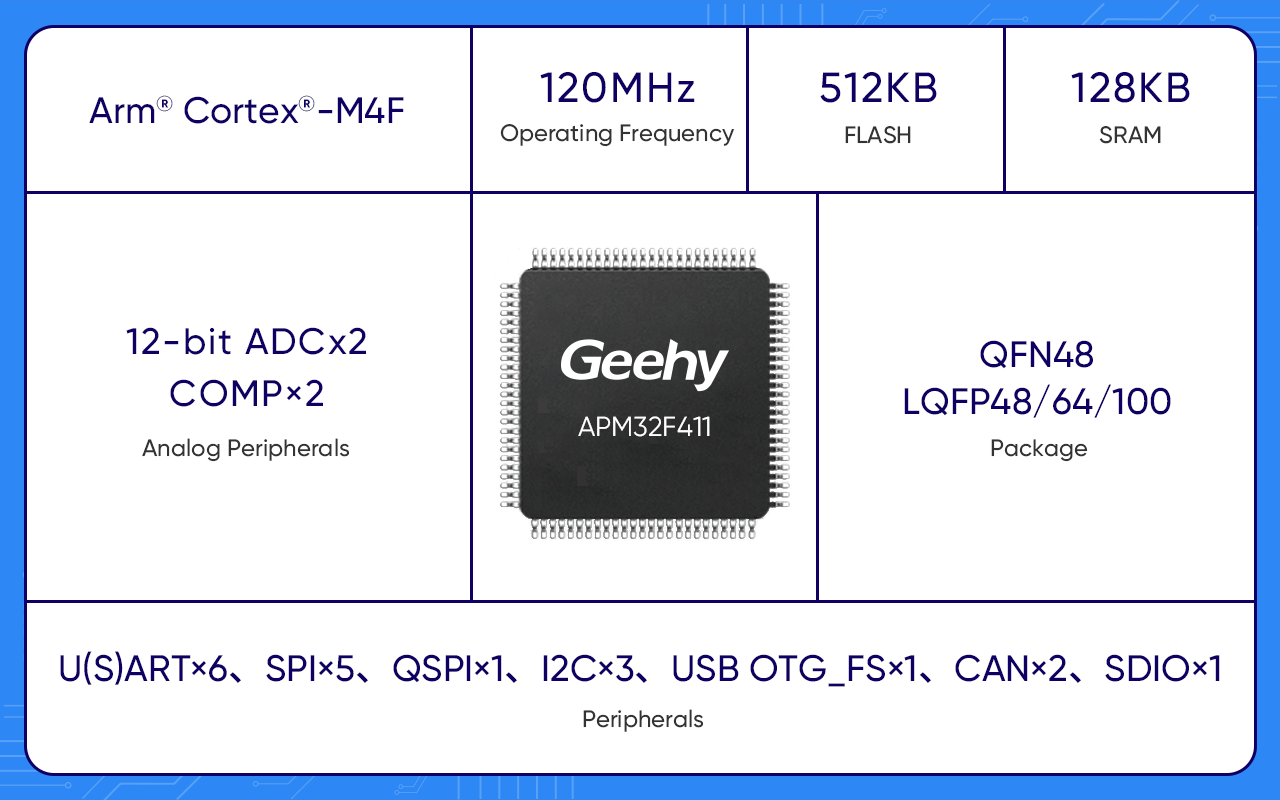

Performance Advantages of the APM32F411 MCU

· Utilizes a Cortex-M4F core running at 120MHz.

· Offers 512KB Flash and 128KB SRAM, suitable for simultaneous communication with BMS systems, bidirectional inverter modules, and display modules.

· Includes built-in U(S)ART ×6, SPI/I2S ×5, I2C ×3, CAN ×2, USB, SDIO, and SMC interfaces for connecting current sensors, RTC, EEPROM, and LCD modules, achieving diverse functionality and rapid response control.

· Features a high-precision 12-bit ADC module for accurate temperature and humidity information.

· Integrates an SMC interface for TFT screen drive (8080 interface), enhancing the user experience.

The APM32F411 MCU is widely used in BMS, power equipment, charging stations, motor applications, 3D printing, robotics, drones, and various scenarios. It offers high-cost performance, strong stability, high anti-interference, consistent performance, stable supply cycles, and a mature development ecosystem, helping customers enhance product competitiveness, shorten design cycles, and expedite time-to-market.