Working Principle of Thermal Printer

A semiconductor heating element is installed on the print head to control the heating element on the printer core. After receiving the print data, the thermal printer converts the print data into bitmap data, and after the print head is heated and contacted with the thermal printing paper, it can print out the required pattern and text.

Classification of Thermal Printers

According to the arrangement of their thermal elements:

Thermal Serial Dot System: Columnar thermal is an early product and is mainly used in some applications where the printing speed is not high.

Thermal Line Dot System: Line heat is a technology of the 1990s, and its printing speed is much faster than that of column heat, and the fastest speed has reached 350mm/sec.

To achieve high-speed thermal sensitive printing, besides selecting a high-speed thermal sensitive printing head, the corresponding control board must be matched with it.

Geehy 2/3/4-Inch Thermal Printer Solution

It is mainly composed of a control circuit, stepper motor driver, thermal film, human-machine interaction, and peripheral circuit. The MCU in the control circuit is used to dynamically process the image characters and control the peripheral devices. The MCU receives the print command and subsequently sends the dot matrix data to the print head through the SPI interface to complete the data conversion while detecting the print head temperature and controlling the stepper motor for precise paper rolling, key presses, and other operations.

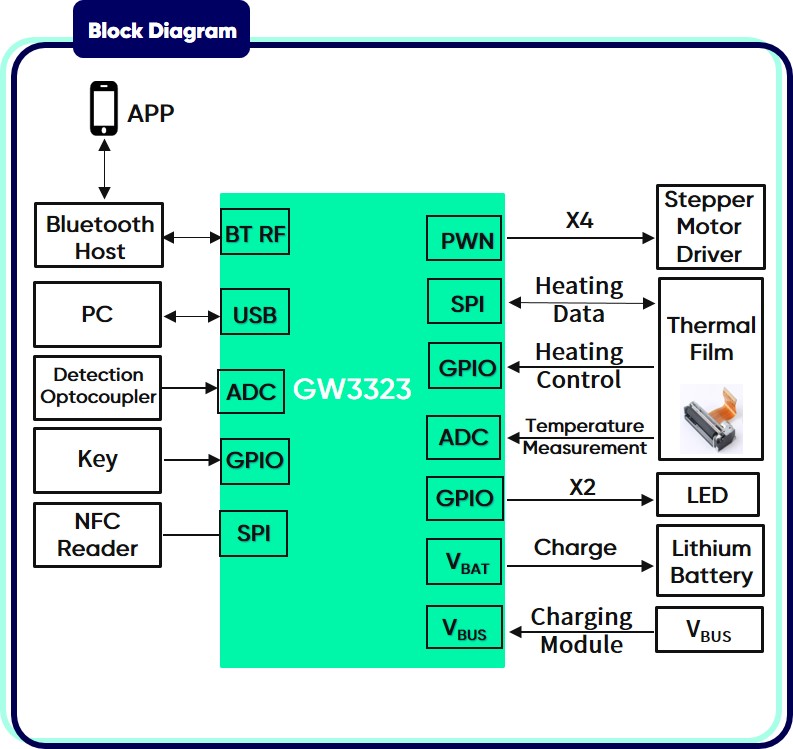

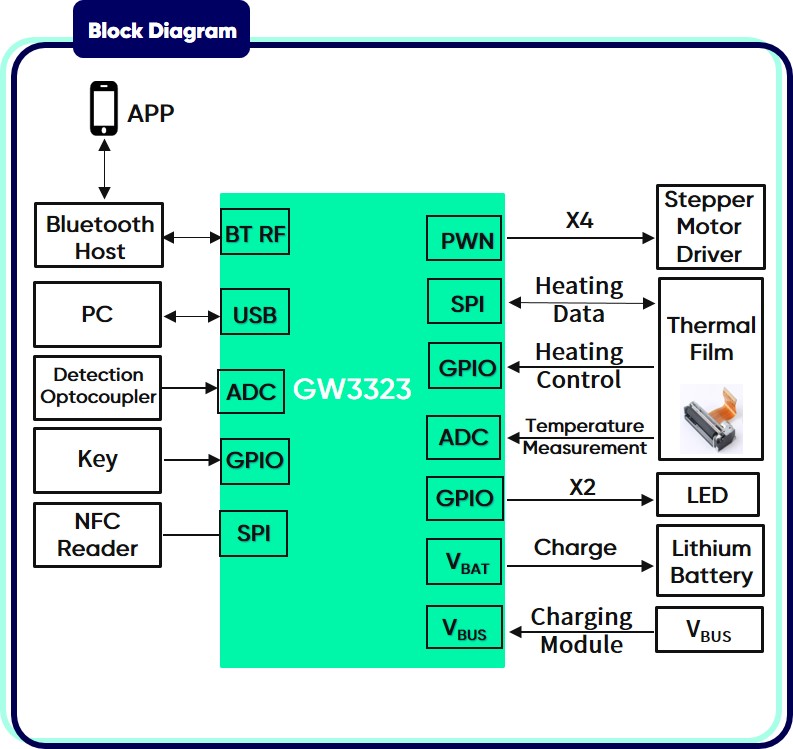

GW3323 2-Inch Bluetooth Thermal Label Printer Solution

As one chip can realize Bluetooth phone pairing and thermal printer control, the solution is very cost-effective and can be used for labeling groceries, household items, and cables. With rich interfaces and reliable transmission, the master chip can effectively guarantee stable output and no need for multiple serial interrupt services. The ADC determines whether overheat protection is needed by detecting the thermistor value and whether the paper is running out by detecting the optocoupler output.

Features

• Based on GW3323 dual-mode Bluetooth 5.2 wireless MCU

• Compatible with iOS and Android devices

• Printing method: direct thermal

• Resolution: 203dpi

• Printing speed: 18mm/s

• Printing width: 15~48mm

• Printing paper NFC identification

• Power supply: 3.7V lithium battery

• Ultra-low standby

• Bluetooth-connected mobile App, easy to edit

Solution Advantages

1. The maximum TX power is +9dBm, receiving sensitivity is -94dBm (2Mbit/s EDR)

2. External NFC chip to achieve printer calibration and better ensure print quality

3. 4-way PWM to achieve precise control of progressive motors

4. High-speed SPI and accurate ADC effectively guarantee the printing effect

5. Save the charging module and Bluetooth module, reducing BOM cost

6. Small main board reduces the difficulty of PCB wiring

7. Built-in Bluetooth protocol stack to ensure faster and more stable data reception

8. A complete SDK makes development easier and less prone to errors

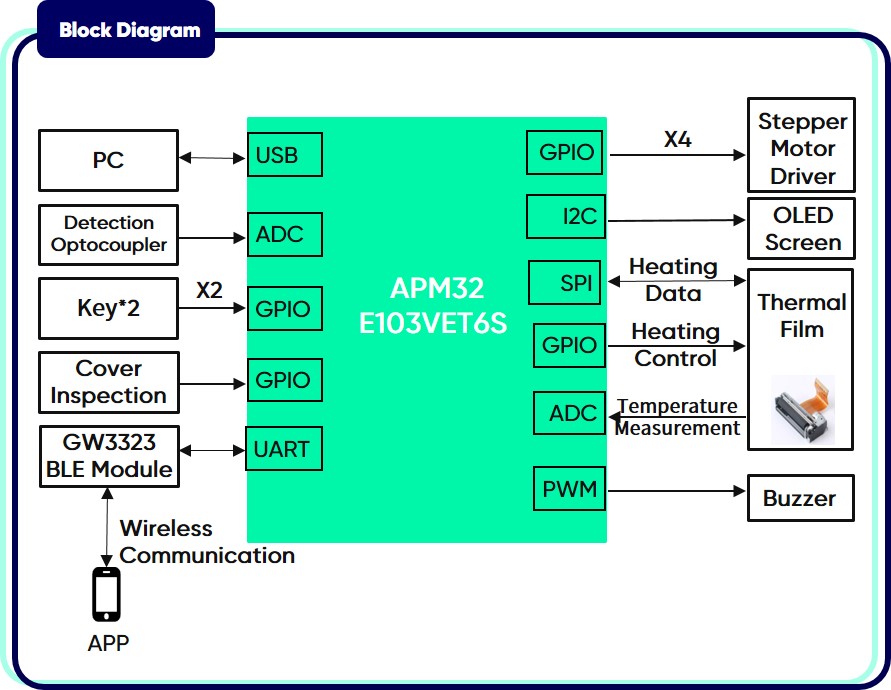

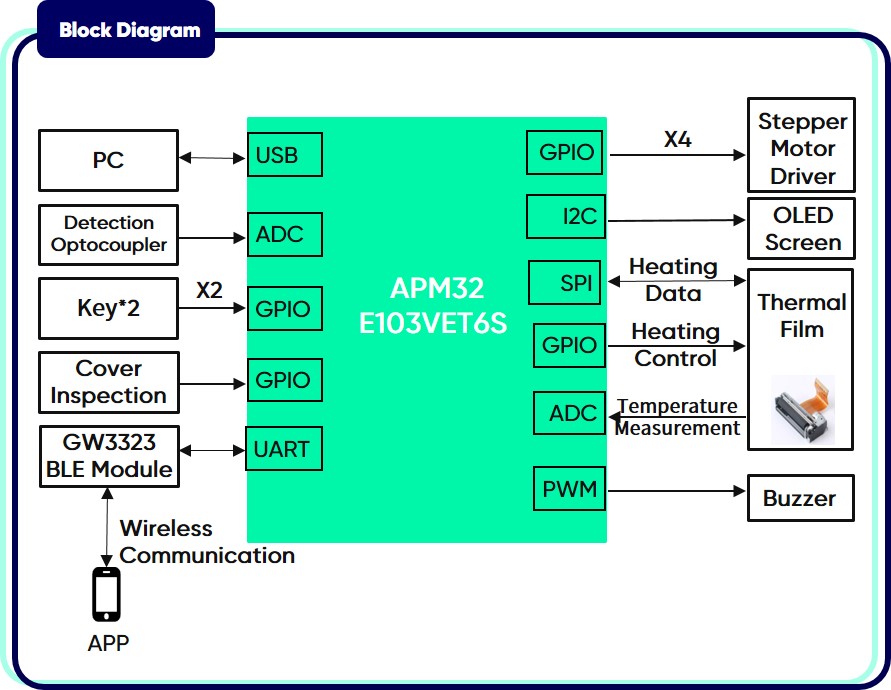

APM32E103VET6S 3-Inch Thermal Printer Solution

Adopting APM32's first E-series industrial-grade enhanced APM32E103VET6S MCU, based on APM32F103xE performance, its frequency, storage, and interfaces have been comprehensively optimized and upgraded, which meets users' needs for more development applications. Certified IEC 60730 and LQFP100 package, this solution can be used to print a variety of labels or tags for warehouse inventory, groceries, milk, jewelry, garments, etc.

Features

● Dual-mode Bluetooth: compatible with iOS and Android devices

● Printing method: direct thermal

● Resolution: 203dpi

● Printing speed: up to 100mm/s

● Printing width: 15~72mm

● UI: working status and power consumption display

● Low power standby > 15 days

Solution Advantages

1. Based on Arm ® Cortex ®-M3 core, supports mainstream IDEs like Keil, IAR, Eclipse

2. A complete SDK makes development easier

3. With cost-effective dual-core SDRAM

4. Support vector fonts and built-in multi-language dot matrix fonts

5. Support commonly-used 1D & 2D barcode types

6. Compatible with SPL, CPCL, and ESC commands

With rich resources and support for multiple mainstream development environments, Geehy’s industrial & automotive-grade MCUs make thermal printer applications extremely flexible and cost-effective. It provides technical support including user manuals, SDK routines, DEMO boards, debugging, and mass production tools to help customers simplify their designs and complete product development quickly.