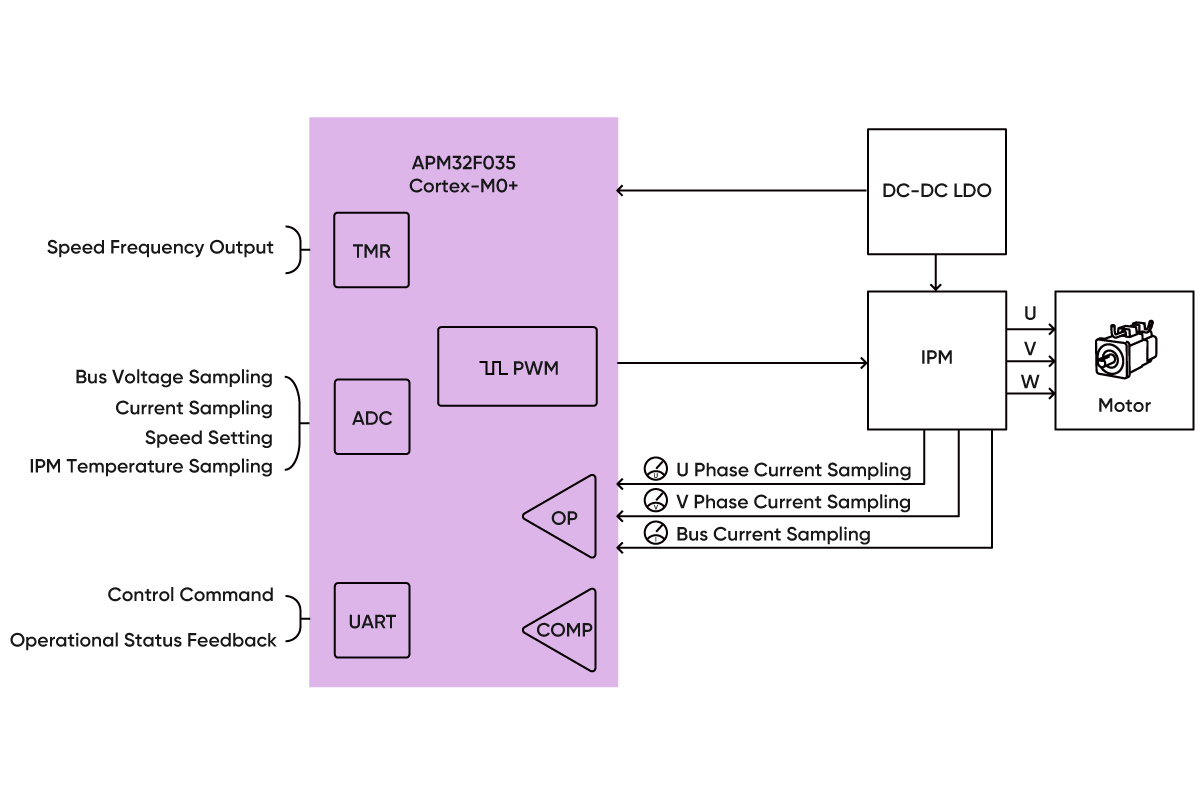

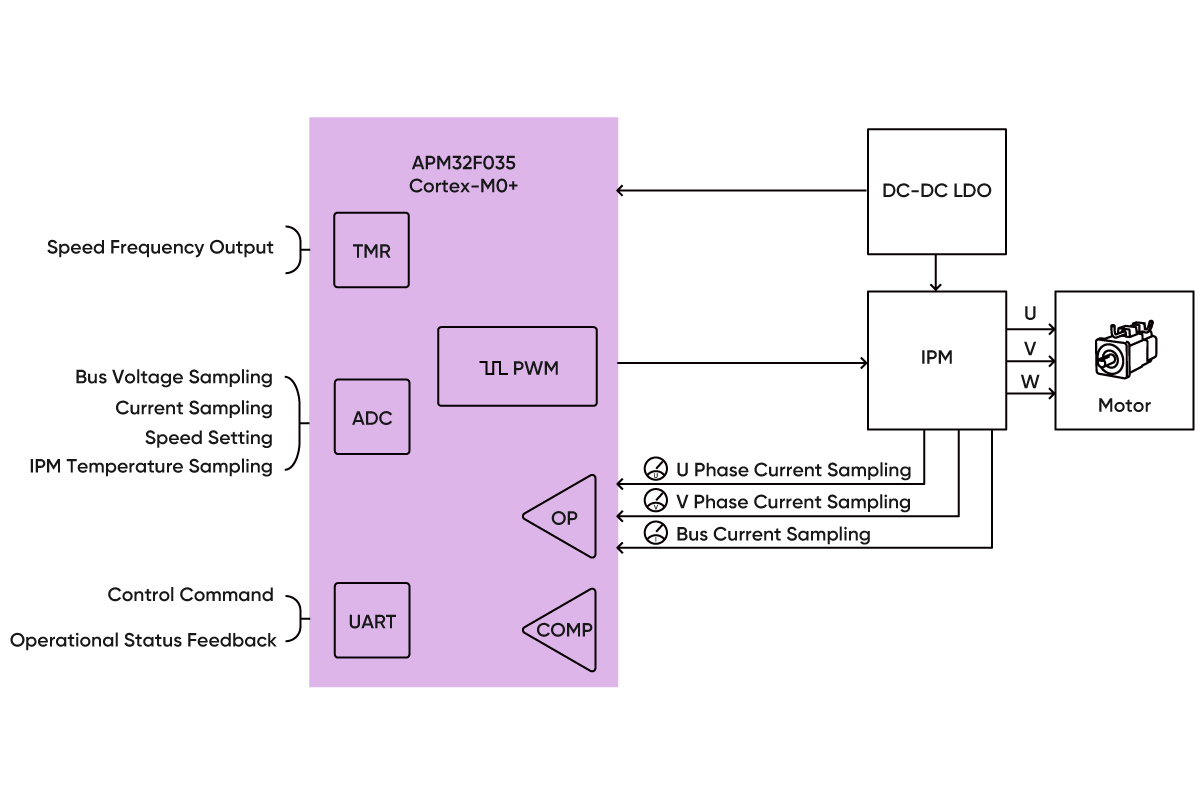

Based on the APM32F035 motor control MCU, Geehy’s canned motor pump solution elevates the entire system to achieve high-efficiency and energy-saving levels comparable to IE3 standards. The compact and stable circuit design offers superior cost-effectiveness compared to traditional approaches. The APM32F035, acting as the main control chip, handles signal sampling (bus voltage, current, IPM temperature), executes motor control logic, and receives control commands.

With abundant resources, the APM32F035 MCU enables simplified circuits and reduced interference, and the M0CP coprocessor supports more intricate calculations with shorter processing times. This boosts motor operational efficiency, introducing application protection functions like fault indication, bidirectional rotation switching, software, and hardware speed control, input over/under-voltage protection, software and hardware over-current protection, phase loss protection, and stall protection. These features ensure the motor operates efficiently, smoothly, quietly, and safely.

Block Diagram of APM32F035 Canned Motor Pump Solution

Key Features of APM32F035 Canned Motor Pump Solution

▪High-performance 32-bit FOC vector control MCU.

▪ Hall FOC vector control for reduced operational noise.

▪ Integration of multiple op-amps and comparators for streamlined circuits and reduced interference.

▪ Hall self-learning and angle compensation functions for absolute zero-degree control, enhancing motor efficiency.

▪ Smooth operation across speeds from 100rpm to 5000rpm with ultra-high reduction control.

▪ Fault indication, software, and hardware speed control.

Key Advantages of APM32F035 Motor Control Dedicated MCU

▪ Arm® Cortex®-M0+ core, 72MHz high main frequency.

▪ Flash 64KB, SRAM 10KB, BootLoader 4KB.

▪ M0CP coprocessor for faster, more complex calculations.

▪ Analog peripherals: OP-AMP×4, COMP×2, 12-bit ADC×1.

▪ Digital peripherals: SPI×1, U(S)ART×2, I2C×1, CANx1, DMA.

▪ Motor-specific PWM: Supports complementary, brake, and can be linked with M0CP.

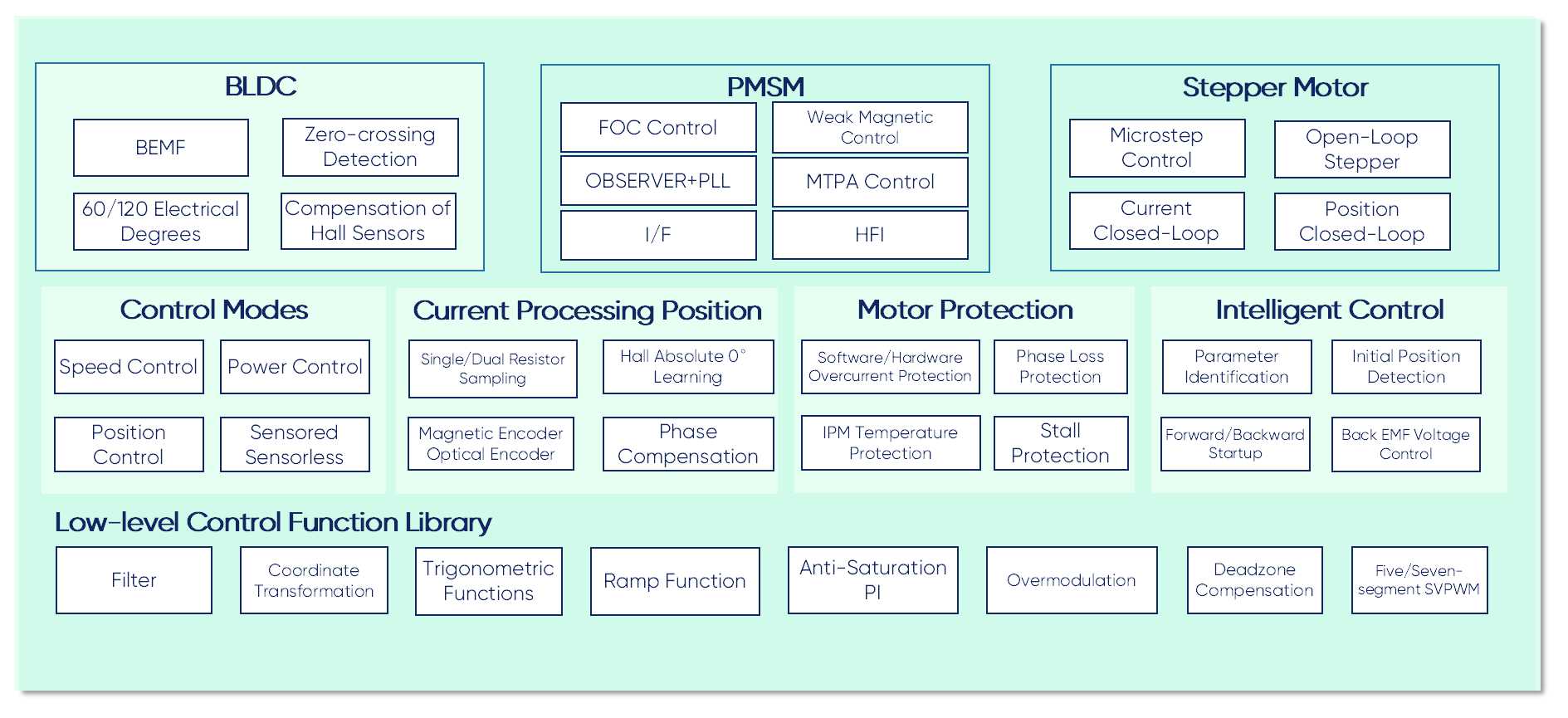

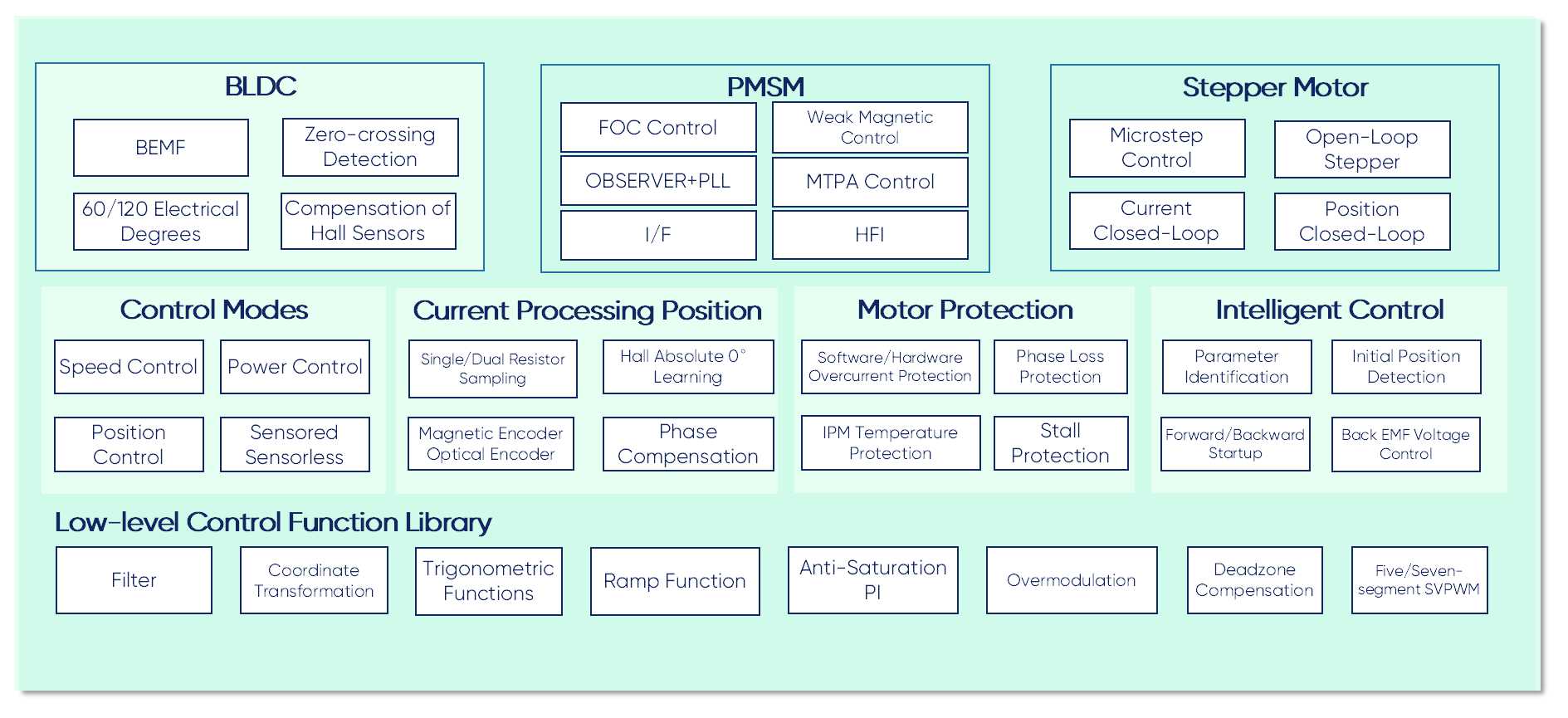

Leading System-Level Ecosystem for Efficient Mass Production

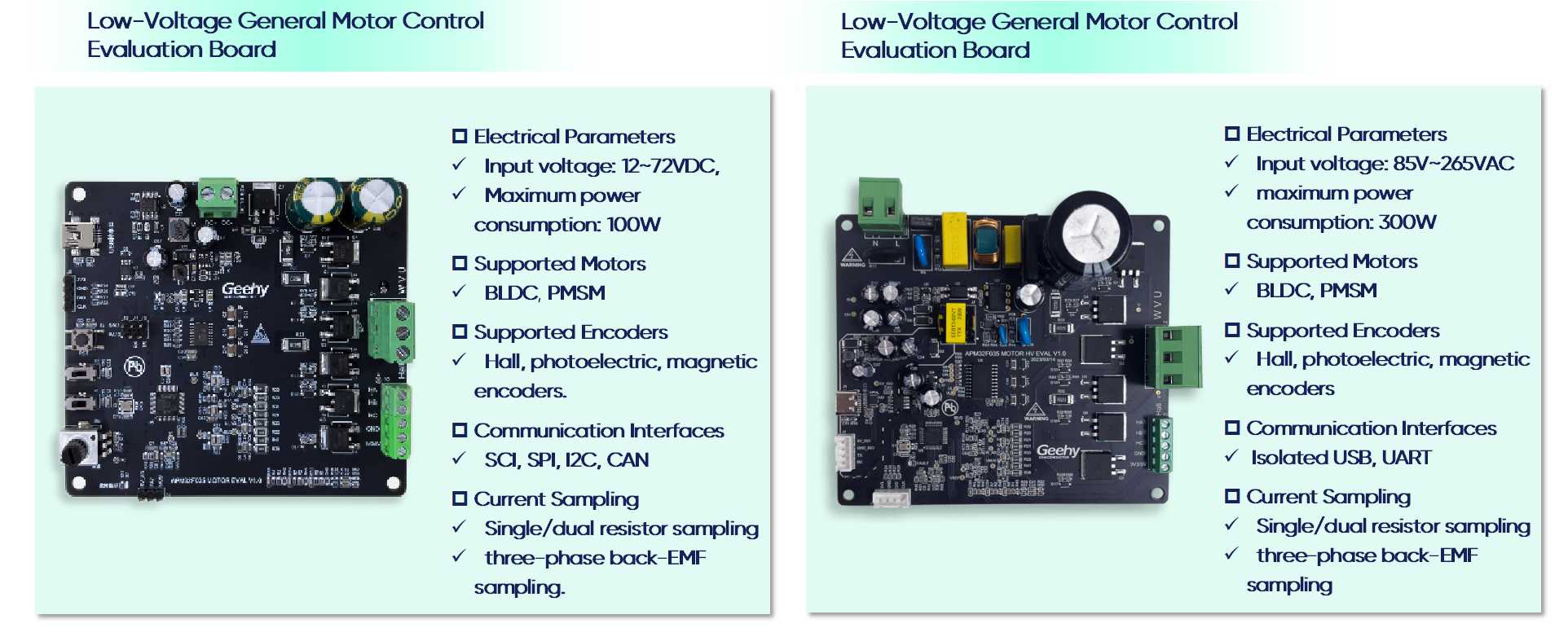

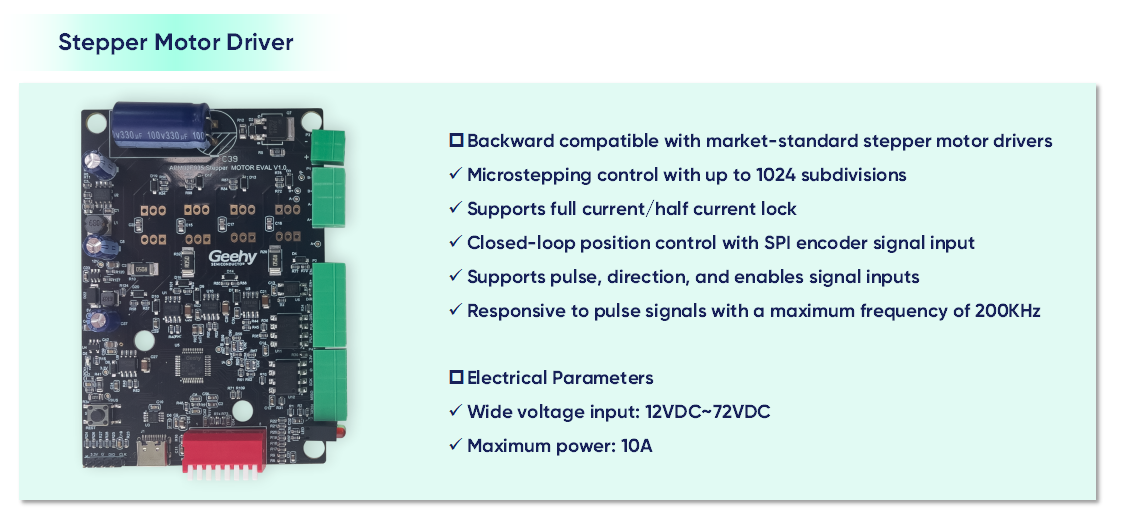

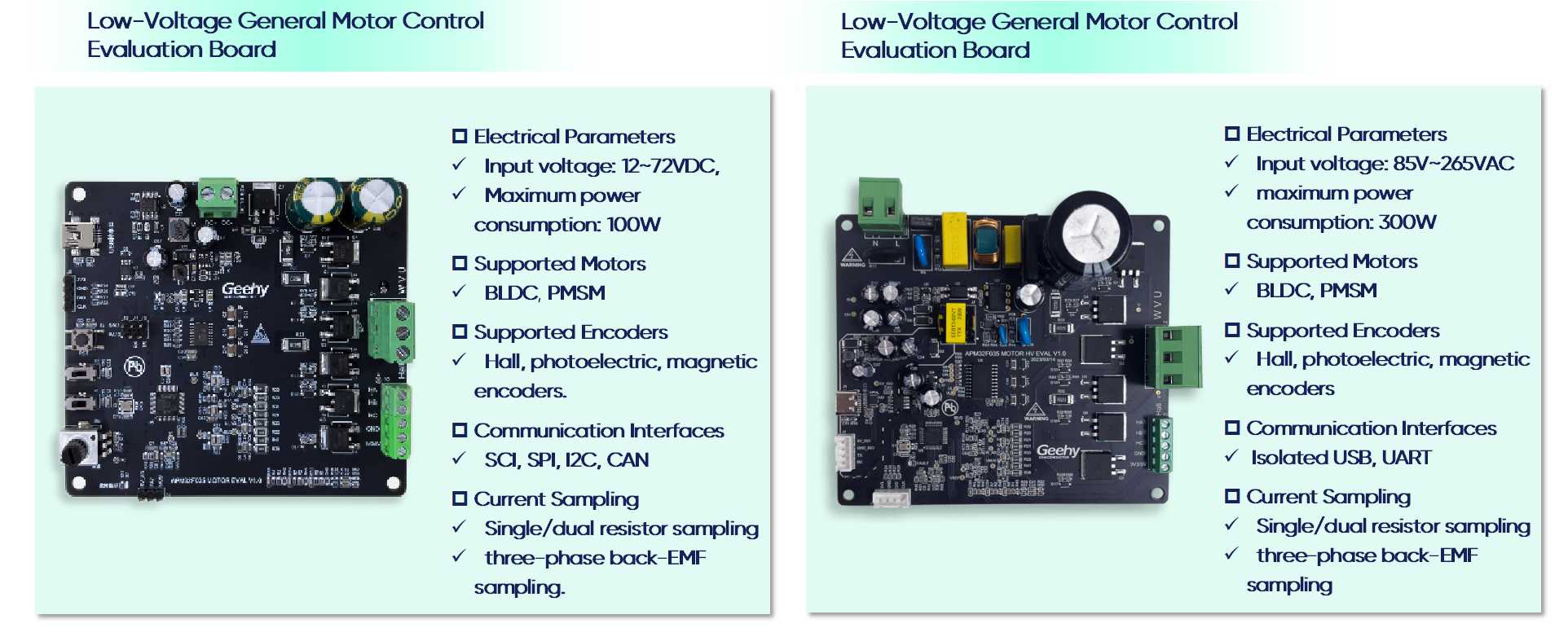

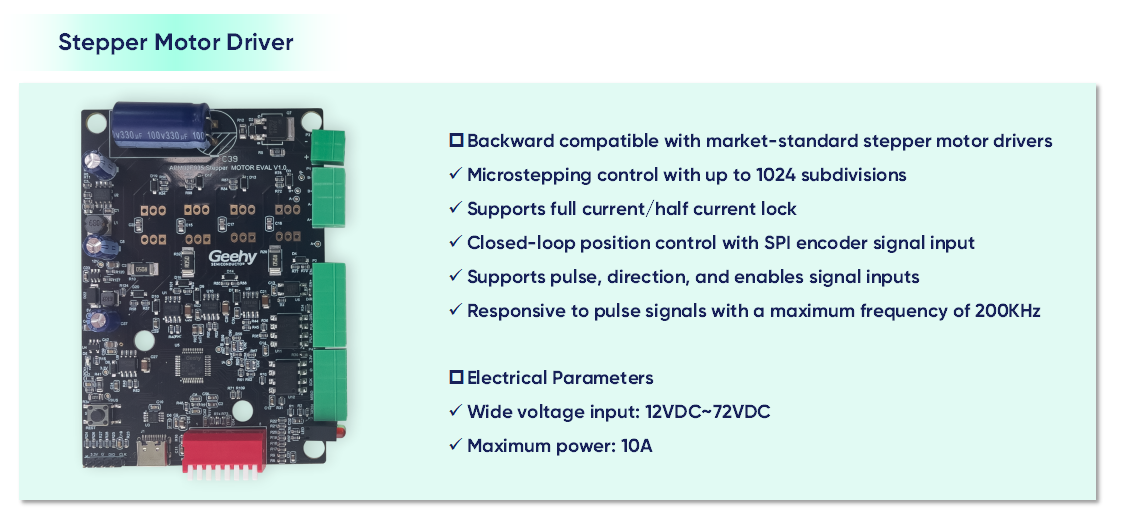

Tailored to the working principles and diverse operating conditions of canned motor pumps, Geehy offers a range of optional motor types, including DC motors and asynchronous motors. Our objective is to cater to the varied development needs associated with different motor applications, ensuring prompt delivery for mass production. Geehy's motor control ecosystem platform encompasses multiple layers, starting from the application layer, intermediate layer, device layer, and hardware layer, to the dedicated motor team. This comprehensive platform supports flexible and user-friendly software and hardware development tools. Our offerings include high and low-voltage general motor platforms, stepper motor EVAL boards, low-level register SDKs, customer support for motor-specific calculations, a variety of algorithm choices, access to different control modes, and robust safety protection mechanisms.

Our offerings include high/low-voltage motor EVAL boards and stepper drivers. For more details, kindly reach out to our dedicated sales manager or any of our authorized distributors.