Sensorless motor control eliminates the need for position or speed sensors, such as encoders or Hall sensors. By calculating rotor position and speed from the motor's current and voltage signals, it reduces costs, enhances system reliability, and simplifies motor structure. This technology is increasingly applied in fields like industrial automation, Unmanned Aerial Vehicle (UAV), and outdoor air conditioning, driven by its efficiency and scalability.

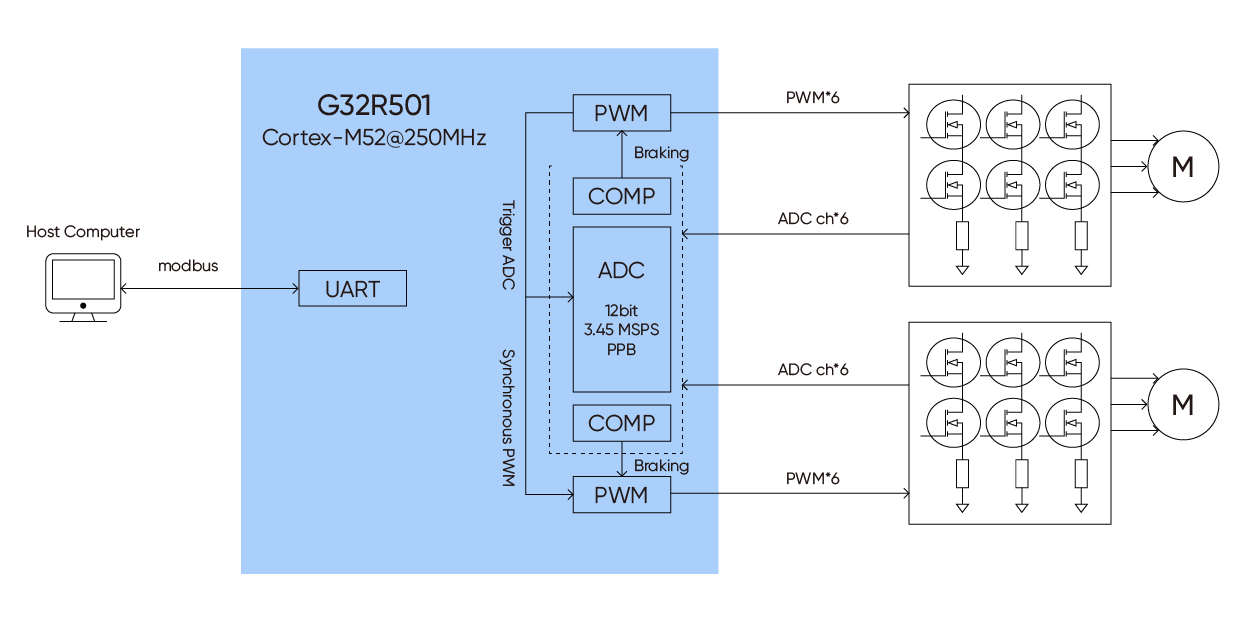

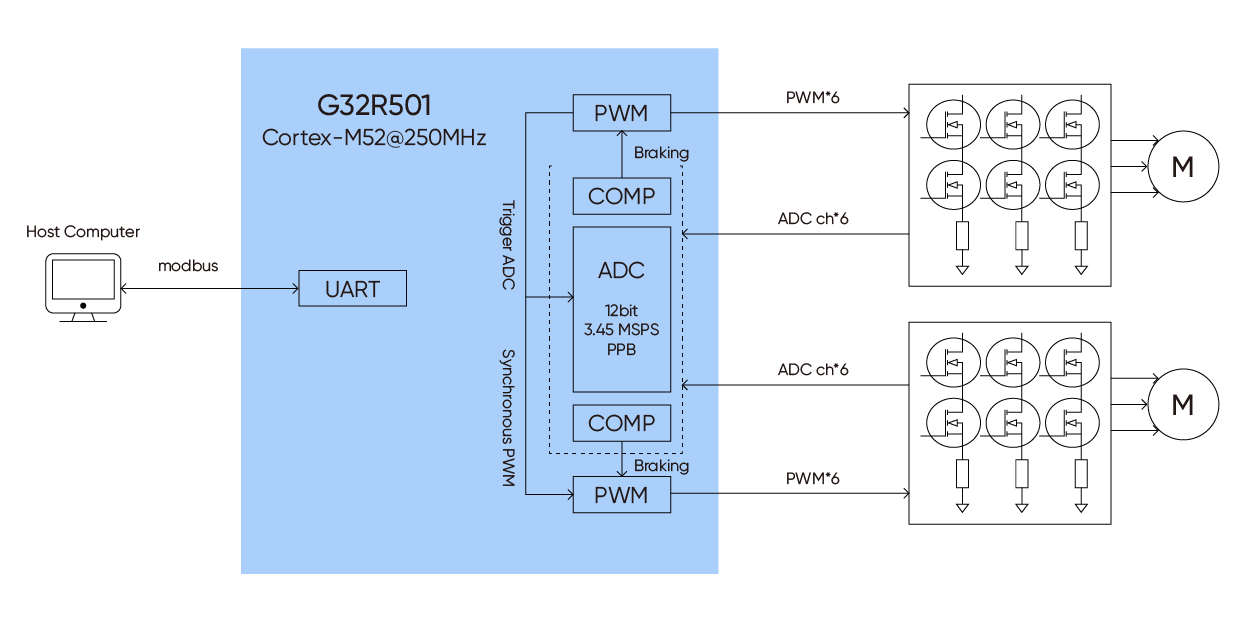

Geehy's G32R501 low-voltage sensorless dual-motor solution leverages the newly launched G32R501 real-time MCU. The solution enables dual-motor sensorless FOC control, offering a highly responsive and precise system with a single core completing current loop control in just 24.8μs. It integrates key features such as motor parameter identification and adaptive control, supporting a wide range of permanent magnet synchronous motors.

Low-Voltage Sensorless Dual-Motor Solution Typical Applications

Low-Voltage Sensorless Dual-Motor Solution Specifications

· Input Power Range: DC 12V–48V

· Peak Output Current: 20A

· Minimum Control Frequency: 1Hz

· Start-Up: Full-torque closed-loop start (target frequency ≥ 4Hz)

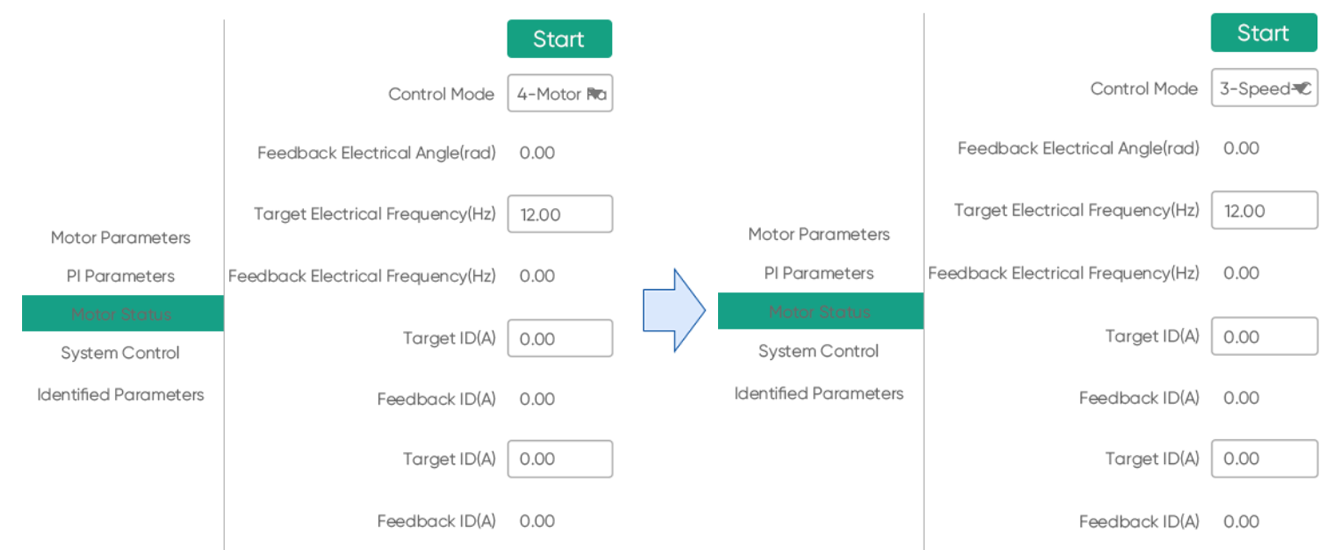

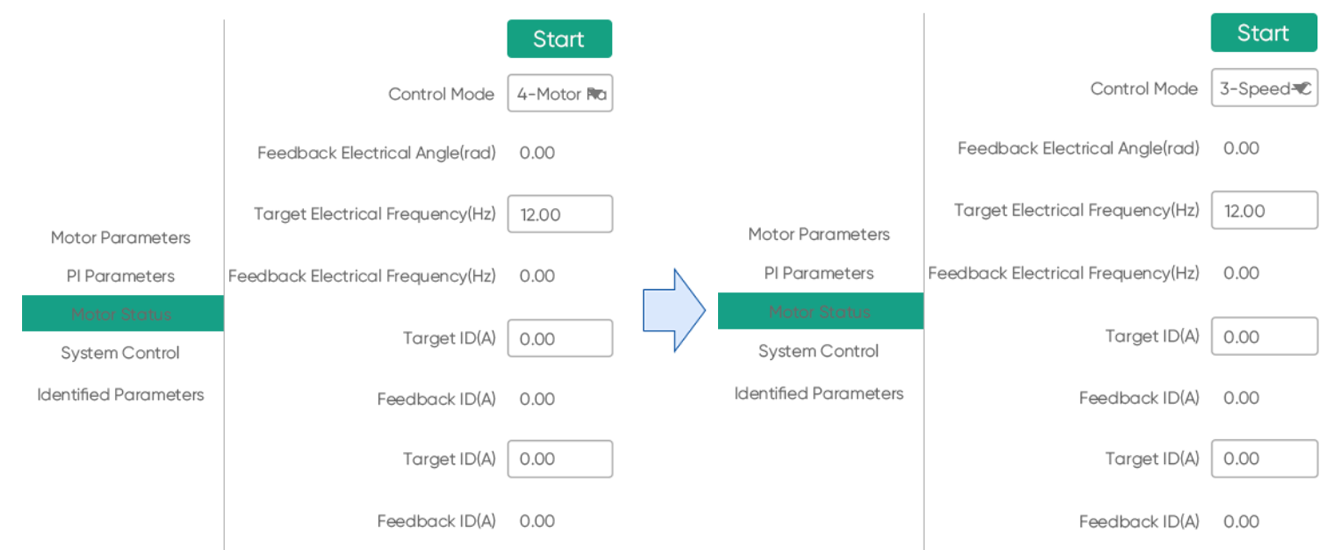

· Control Modes: V/F, single-current closed-loop, dual-loop control

· PI Parameters: Model reference adaptive

· Additional Functions: Power-off parameter retention, software reset

· Motor Parameter Identification: Static identification (resistance, inductance, flux linkage), online resistance identification

· Communication Protocol: Modbus

· Documentation: Host computer software, user manual, and more

G32R501 Real-Time Control MCU Features

· Core & Memory: Based on Arm® Cortex®-M52 dual-core architecture, 250MHz frequency, tightly coupled memory (ITCM, DTCM), I/D-Cache, and Flash prefetch for enhanced real-time performance.

· Extended Instructions: Proprietary Zidian Math Instruction Extension, supporting trigonometric functions, square roots, division, and more.

· Extended Control Peripherals:

- 16 PWM channels with high synchronization for precise low-speed motor control.

- Flexible IP linkage with two additional comparison sub-modules (CMPC, CMPD) for synchronous events, enabling PWM phase synchronization and ADC sampling triggers at any moment during the counting process.

· High-Precision Analog Peripherals:

- Three 12-bit, 3.45 Msps high-speed ADCs for fast, accurate analog signal acquisition, minimizing delay.

- ADCs support 3.3V/2.5V internal reference sources, offering 32% improved voltage resolution with the 2.5V reference for better feedback signal accuracy.

· Communication Interfaces: CAN×2, I2C×1, UART×2, SPI×2, QSPI×1, LIN, PMBus×1.

Hardware and Software Overview

The solution includes a control board and two power boards.

Control Board

· The G32R501 EVAL Board features a CMSIS-DAP debugger and connects to a computer via a Type-C cable for debugging, through isolation for electrical protection during signal transmission, safeguarding the computer from harmful voltages.

· It has two standard pin headers for connecting power boards.

· Communication with Geehy's host computer uses the Modbus protocol for efficient debugging.

Power Board

The power board includes a MOSFET three-phase inverter and a feedback signal circuit, supplying 3.3V to the control board. It connects via standardized pin headers to control the motor.

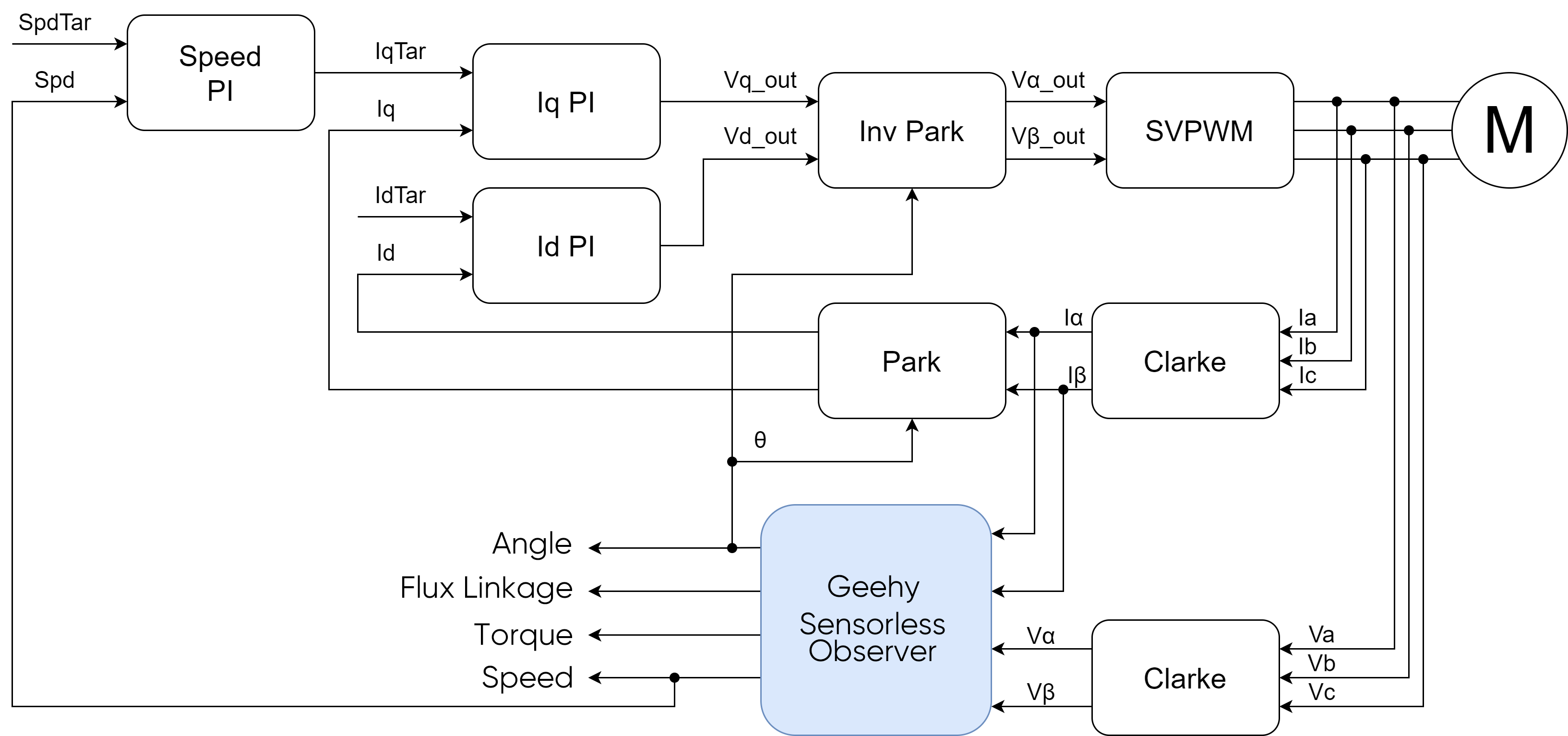

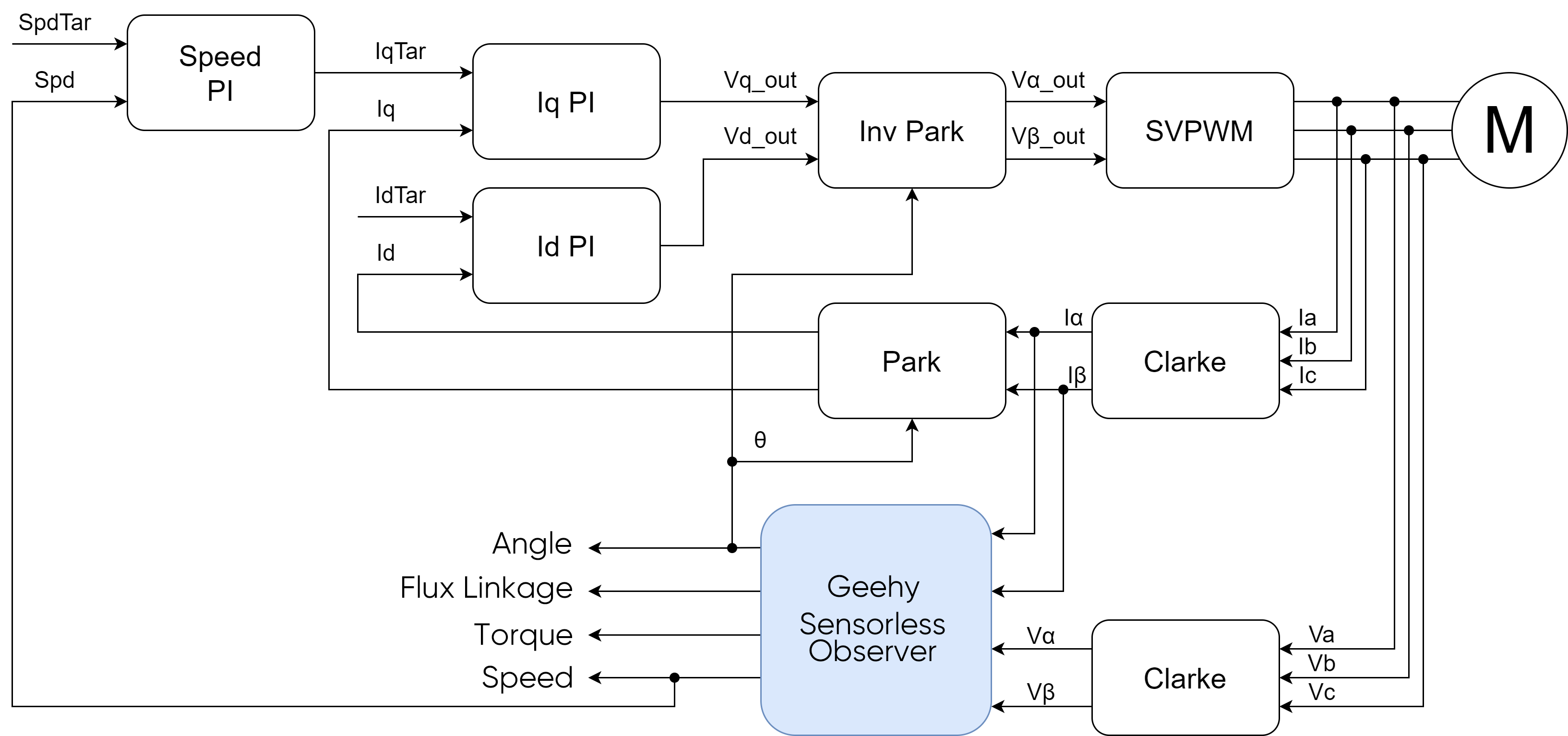

Sensorless Observer

The solution employs a sensorless observer for high-performance sensorless FOC control, offering several advantages over traditional observers:

- Low-Speed Performance: Control frequencies as low as 1Hz.

- Feedback Signals: Monitors flux linkage, angle, speed, and torque for precise control.

- Fast Angle Convergence: Ensures fast response for full-load closed-loop startup.

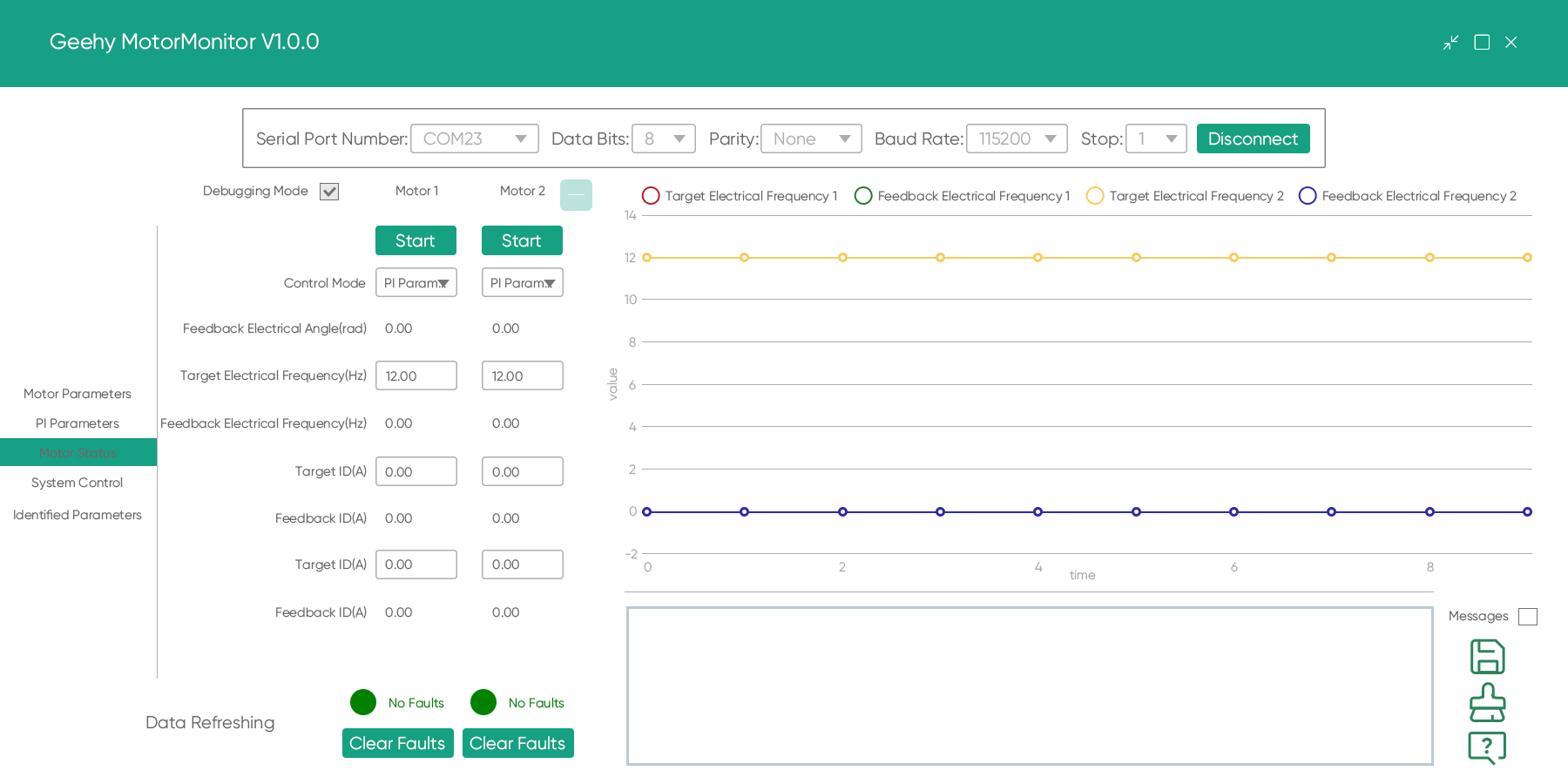

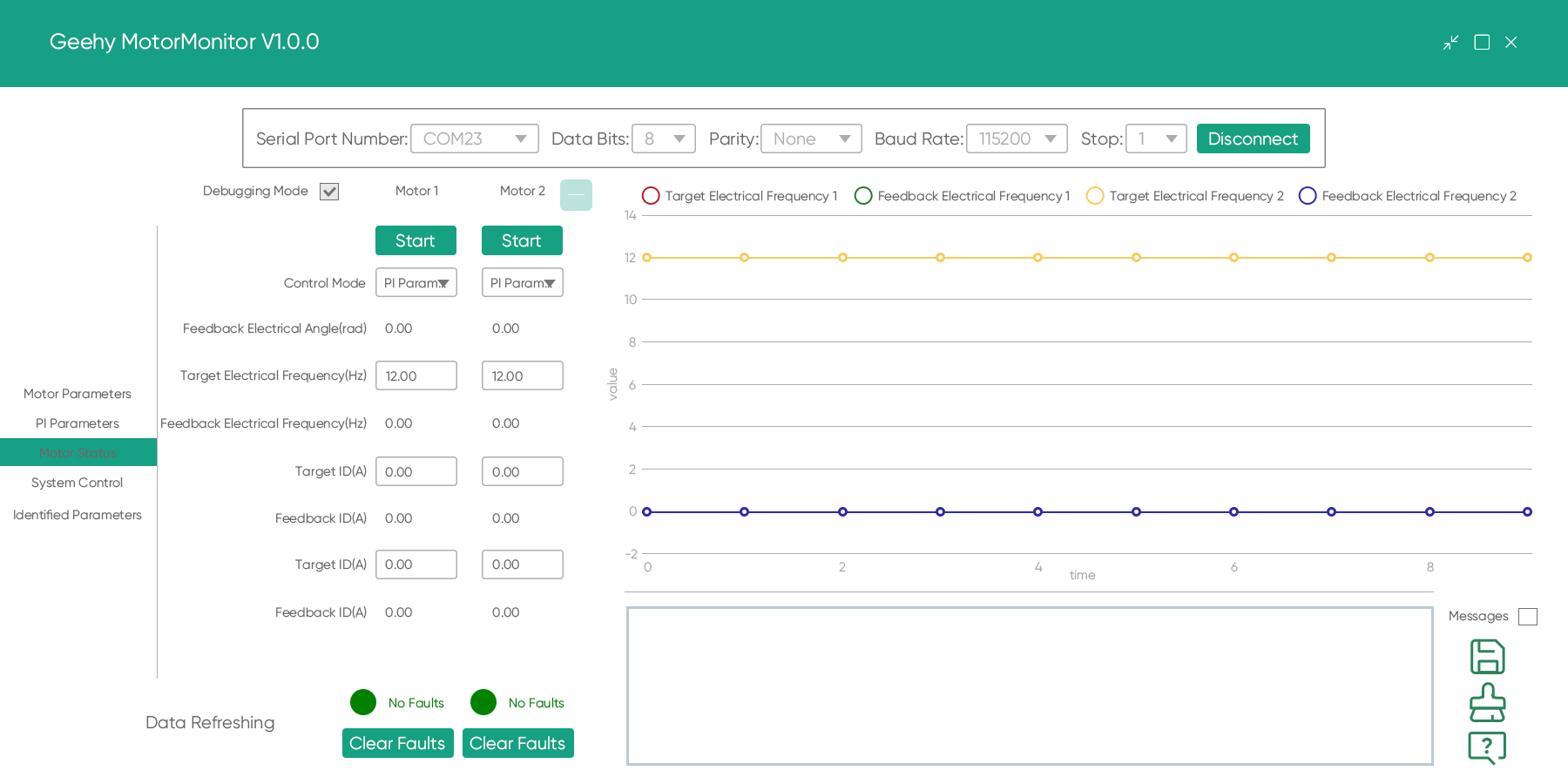

Supporting Host Computer

The solution includes pre-compiled example firmware and a host computer. After programming the firmware and connecting the host, testing can begin immediately.

Usage Instructions

Set the DIP switches and flash the firmware. Then, connect the power supply, motor, and PC as shown. Power on the system and connect the host computer to test motor control functionality.

For new motors, the following process automatically identifies motor parameters, calculates the current loop Kp and Ki, and adapts the motor in minutes:

Set protection and identification parameters→Begin motor parameter identification→Start speed closed-loop control

For detailed instructions, refer to the accompanying user guide.

Geehy’s G32R501 Low-Voltage Sensorless Dual-Motor Solution is a complete hardware and software ecosystem, including the MCU chip, evaluation boards, control algorithms, and example firmware. It accelerates the development cycle for engineers, allowing rapid evaluation and deployment in dual-motor control applications.

As industries increasingly adopt dual-motor control systems to enhance energy efficiency and performance, Geehy’s G32R501 low-voltage sensorless dual-motor solution delivers a versatile, efficient, and easy-to-integrate solution for a wide range of applications. Geehy's real-time control technology team provides comprehensive technical support to help customers meet market demands and accelerate their project timelines.