With global manufacturing shifting toward intelligent, flexible production and service industries accelerating automation, markets for collaborative robots, service robots, and smart-home systems continue to expand rapidly. As robots become deeply integrated into work and home environments, servo systems face higher expectations, requiring ultra-precise control, rapid response, cost efficiency, and compact design. To meet these demands, Geehy introduces a bus-type low-voltage servo solution built on the APM32F425/427 MCU series.

Target Applications

Solution Advantages & Value

· Full Closed-Loop Control Modes

Supports position, speed, and torque control, addressing needs from high-precision positioning to smooth speed regulation and constant-force operation.

· Open Hardware Architecture

Provides extensive interfaces and configurable resources for flexible design, advanced customization, and efficient secondary development.

· Outstanding Dynamic Response

Current-loop update rate and power-stage switching frequency both reach 16 kHz, delivering fast, accurate response for high-speed and dynamic-load applications.

· Visualized Debugging

Features a PC-based tool integrating parameter tuning, real-time waveform display, system monitoring, and fault diagnostics, reducing development effort and accelerating product launch.

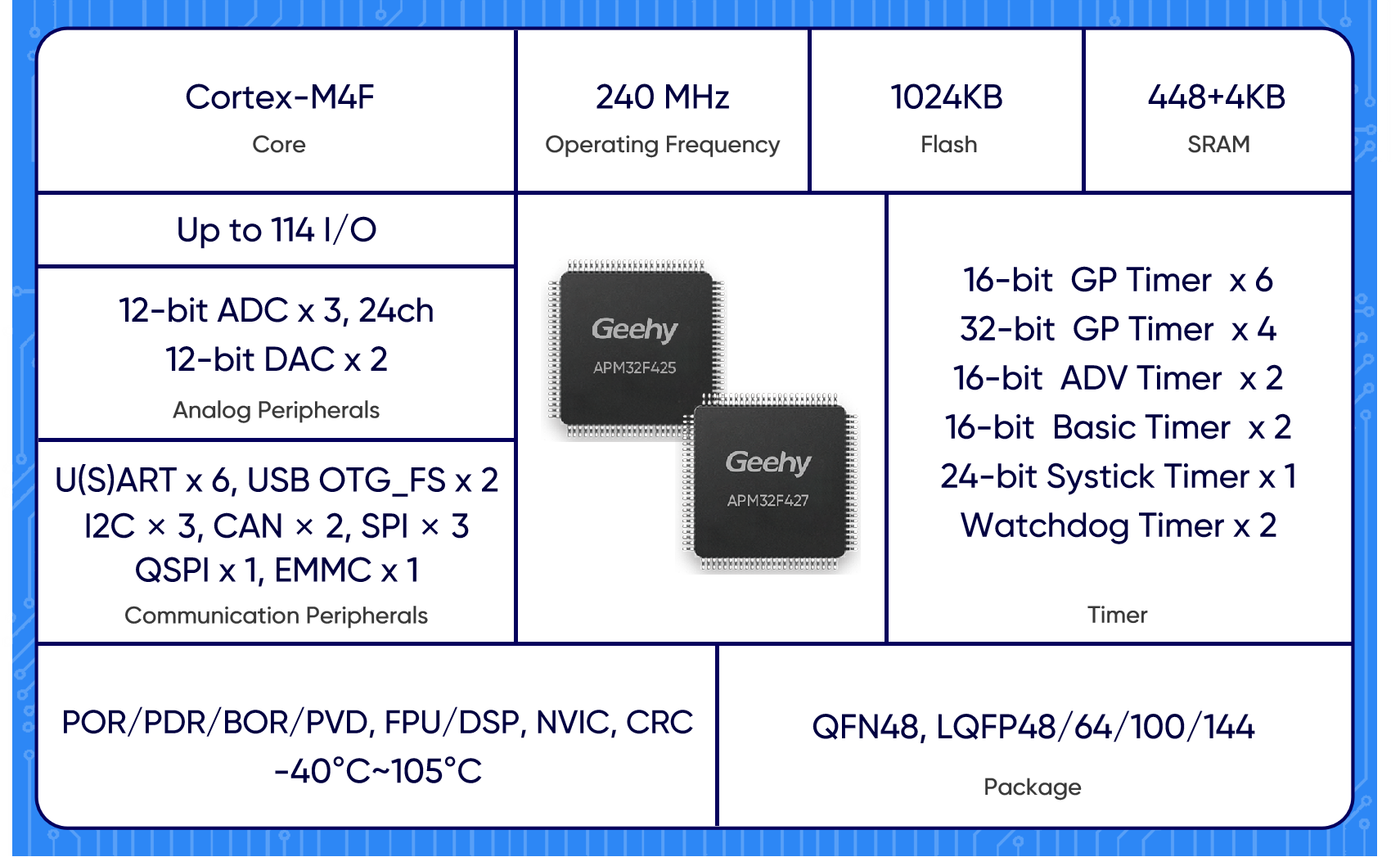

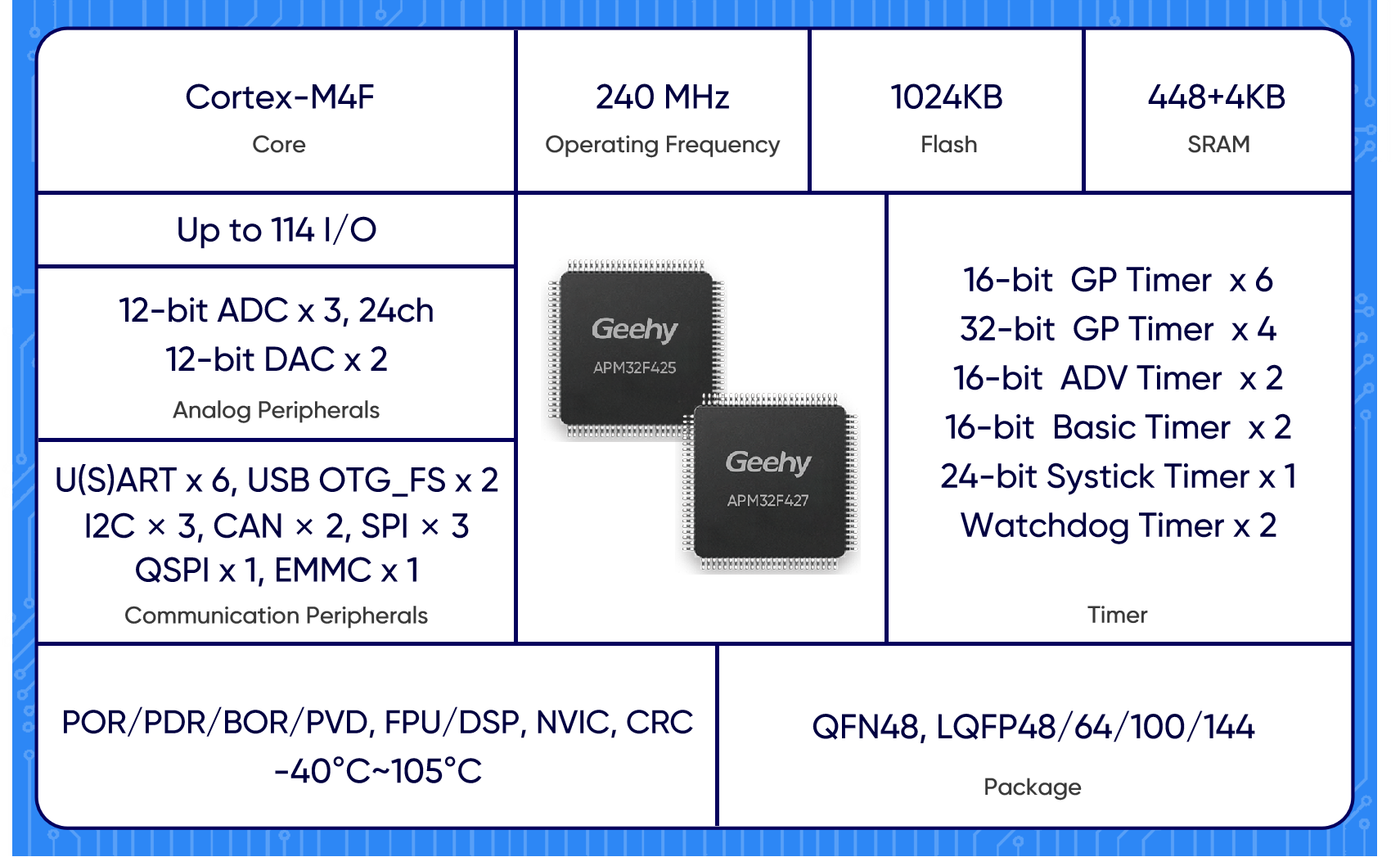

Built on Geehy's independently developed APM32F425/427 high-performance extended MCU series, the solution leverages an Arm® Cortex®-M4F core with up to 1MB eFlash. The APM32F427 series provides 448KB + 4KB SRAM, while the APM32F425 offers 256KB zero-wait-state Flash and 192KB + 4KB SRAM. All devices support up to 240MHz operation across the full temperature range. These architectural advantages deliver shorter execution times and more efficient secondary development.

APM32F425/427 MCU Features

Solution Specifications

· Input Voltage: 20–70 V

· Typical Power: 400 W

· Control Period: 62.5 µs (16 kHz)

· Speed Range: –4000 to 4000 rpm

· Encoder Types: Incremental, absolute (RS485)

· Control Modes: Torque, speed, position

· Rated Output Current (Arms): 10

· Max Output Current (Arms): 25

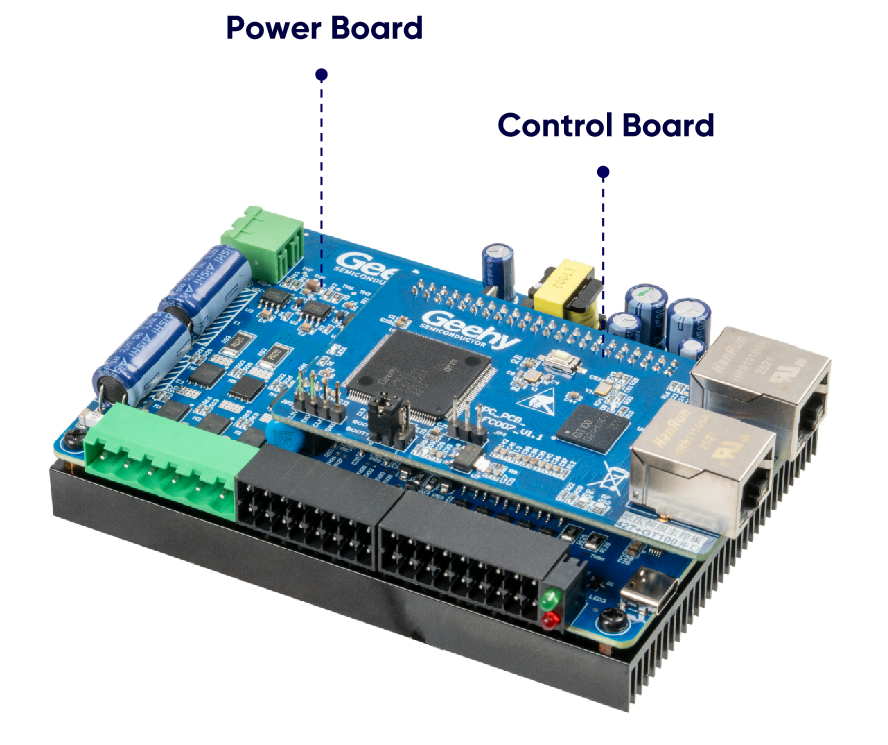

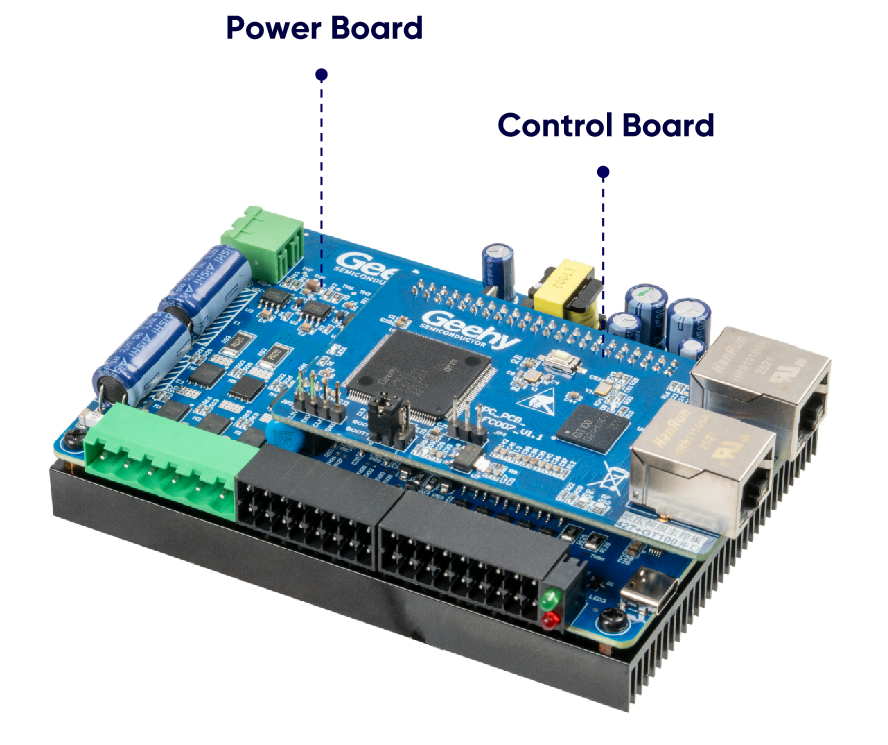

Solution Core

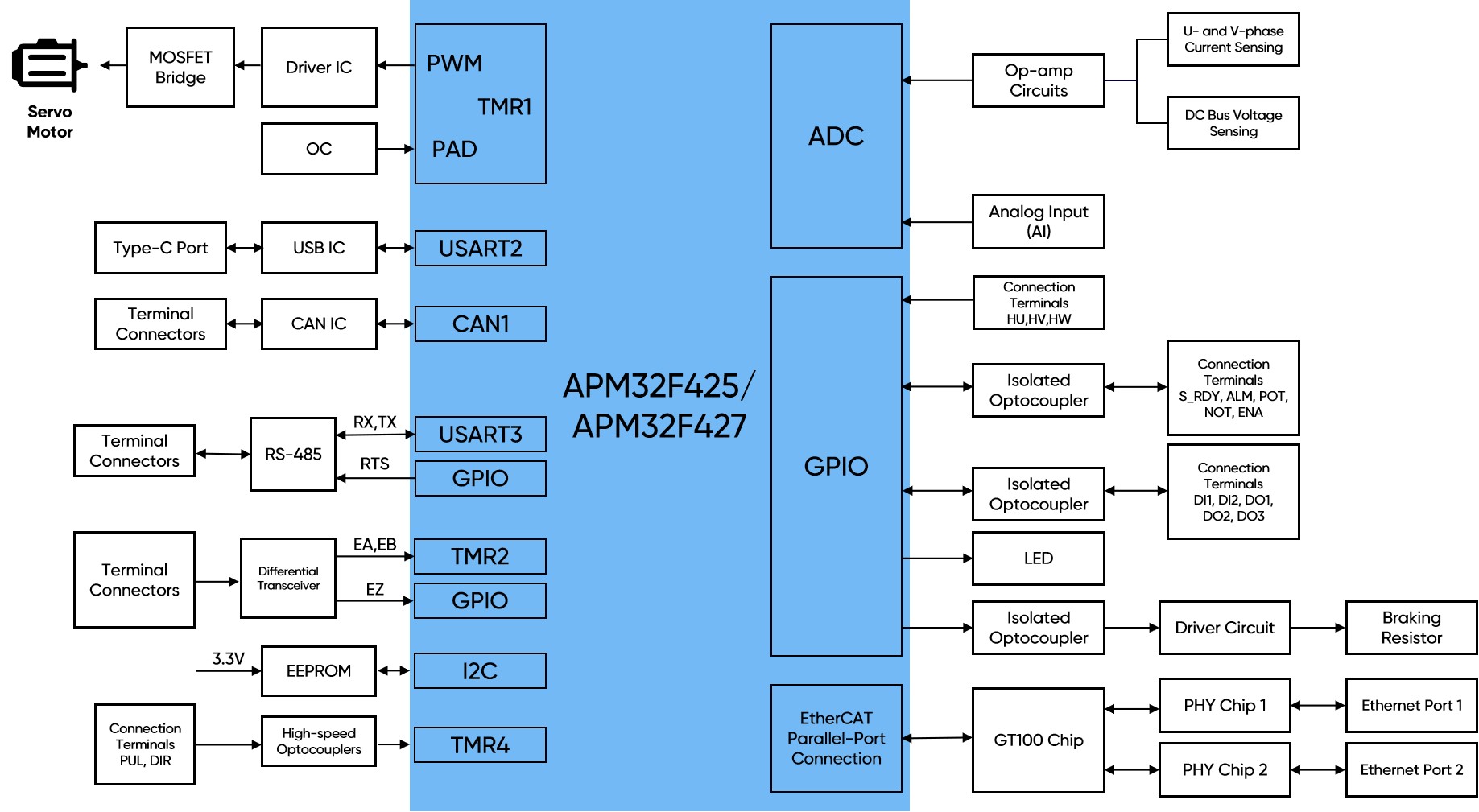

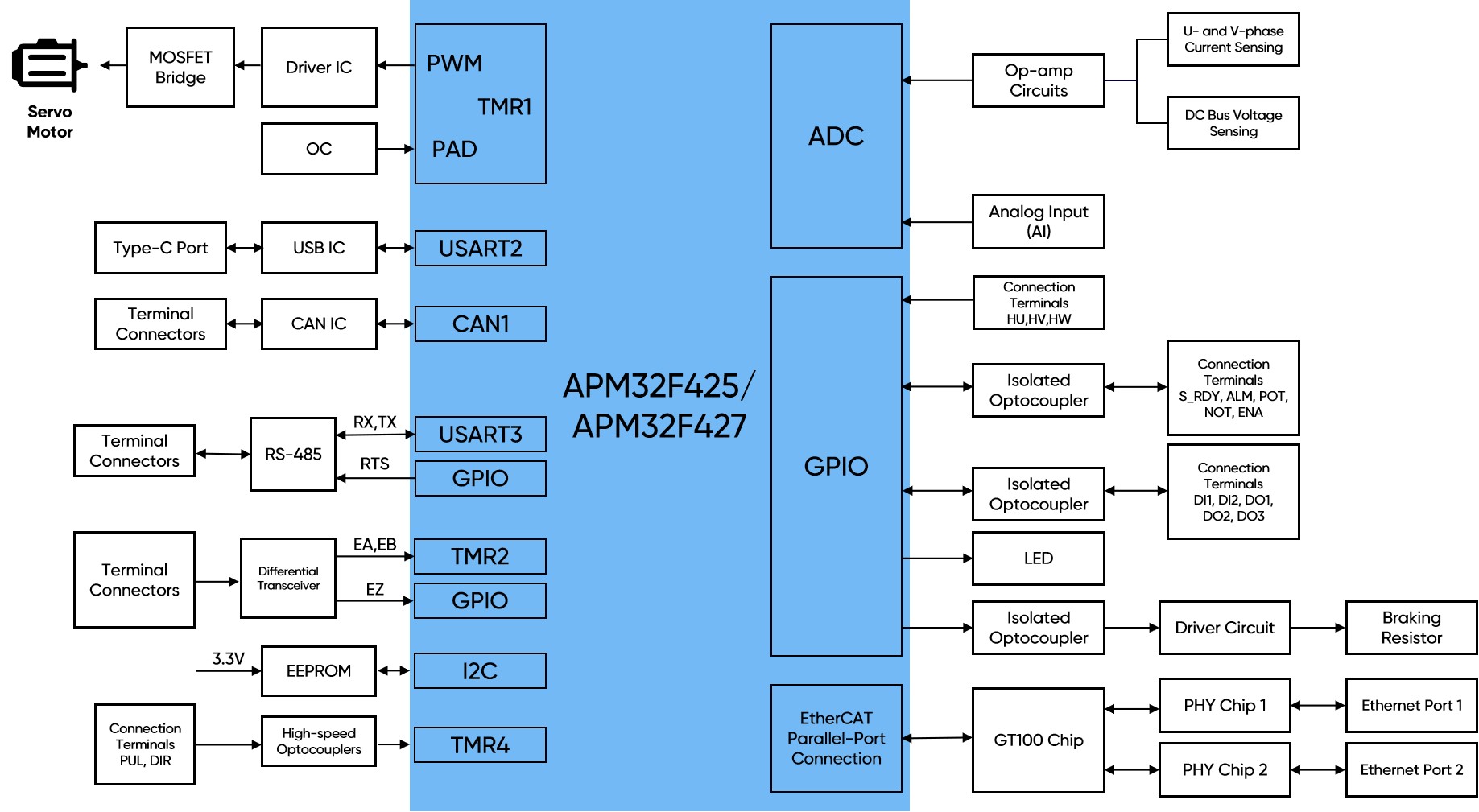

The hardware consists of five modules: power module, control core, signal-processing module, power-drive module, and protection module. Together, they enable closed-loop control of current, speed, and position. Core technologies include high-precision feedback acquisition, optimized PID algorithms, and high-efficiency power-stage driving.

Implementation Methods

· TMR1 timer generates three complementary PWM outputs for vector control.

· High-precision ADC samples two-phase currents for improved accuracy.

· UART or timers communicate with incremental and absolute encoders.

· The parallel interface connects to an EtherCAT slave chip for EtherCAT bus control.

· UART exchanges data with the host PC.

· I²C interfaces with an external EEPROM for storing servo parameters.

· Rich I/O resources support diverse control inputs and status outputs.

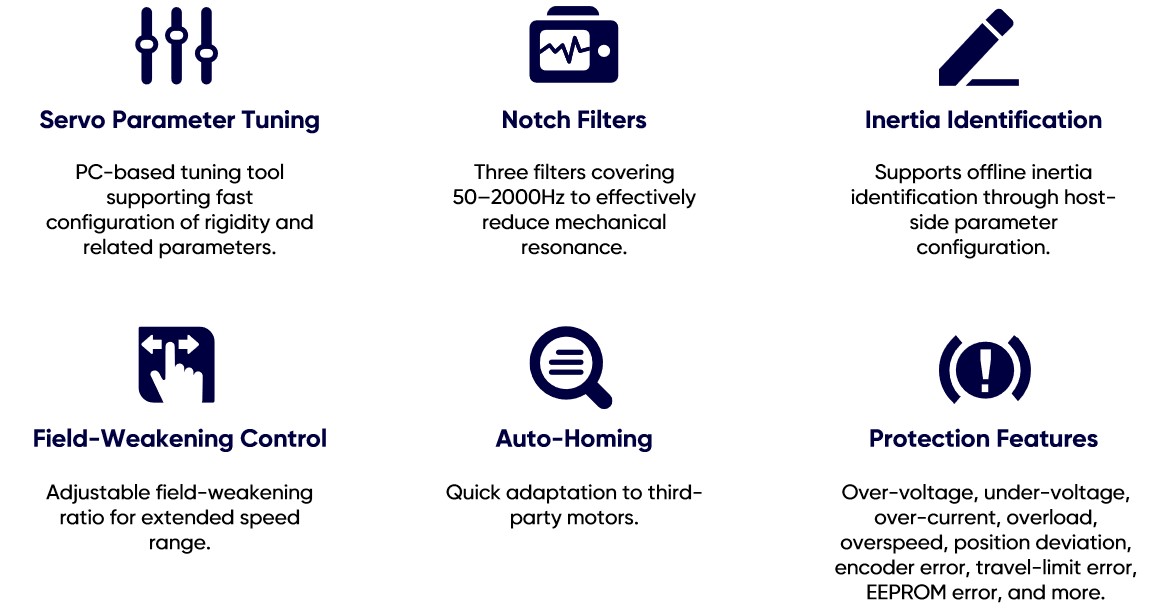

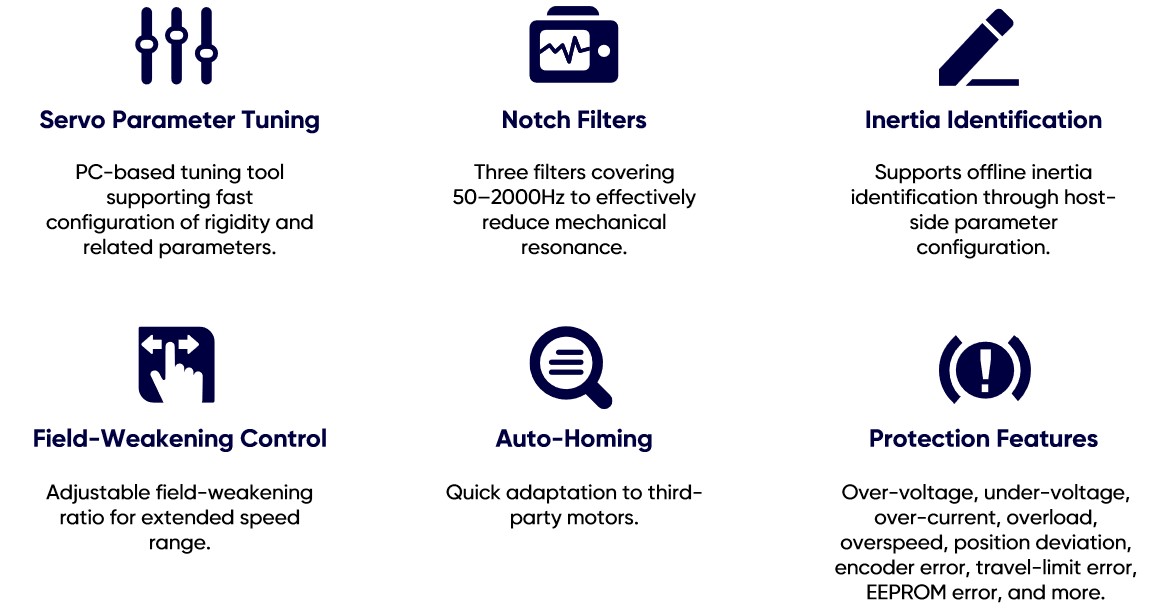

Solution Software

Solution Block Diagram

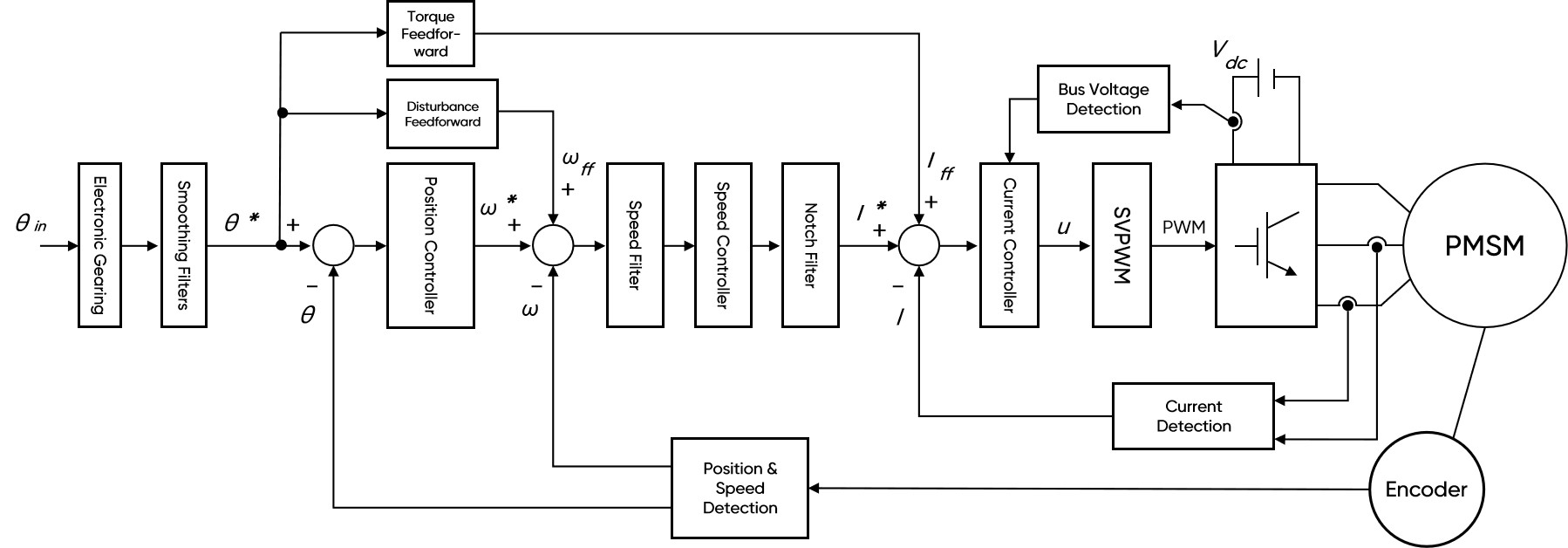

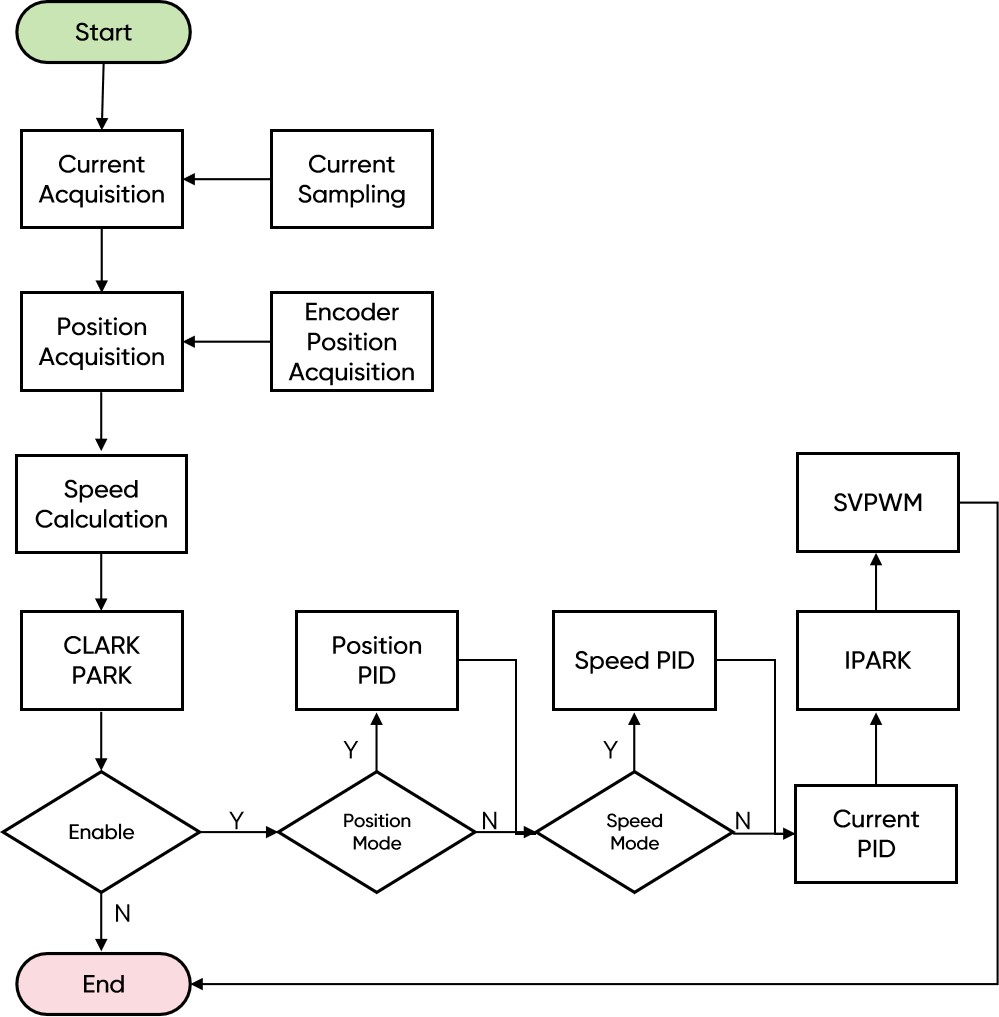

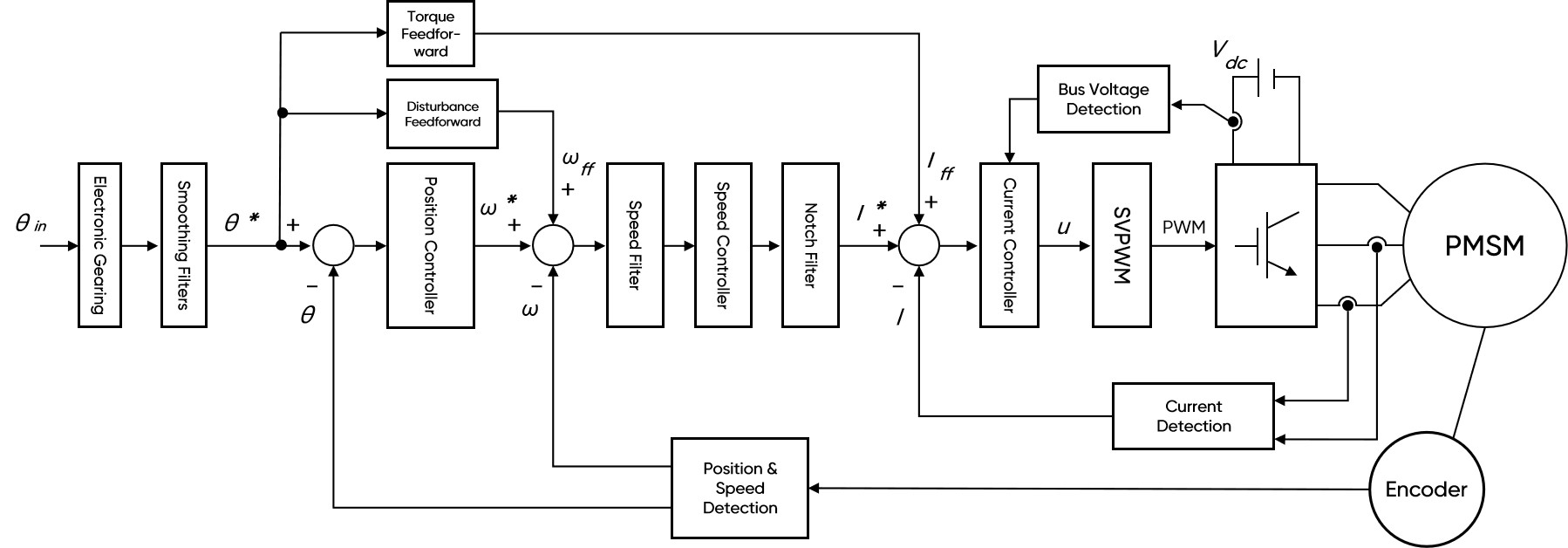

The software adopts a three-loop cascaded control structure:

· Current Loop: Receives commands from the speed loop and ensures fast current tracking. Compensates for DC-bus fluctuations, back-EMF, and system nonlinearities.

· Speed Loop: Receives commands from the position loop or external inputs, ensuring accurate speed tracking and strong disturbance rejection.

· Position Loop: Receives bus-based or IO-based position commands. Provides precise, stable positioning with PID regulation and zero overshoot.

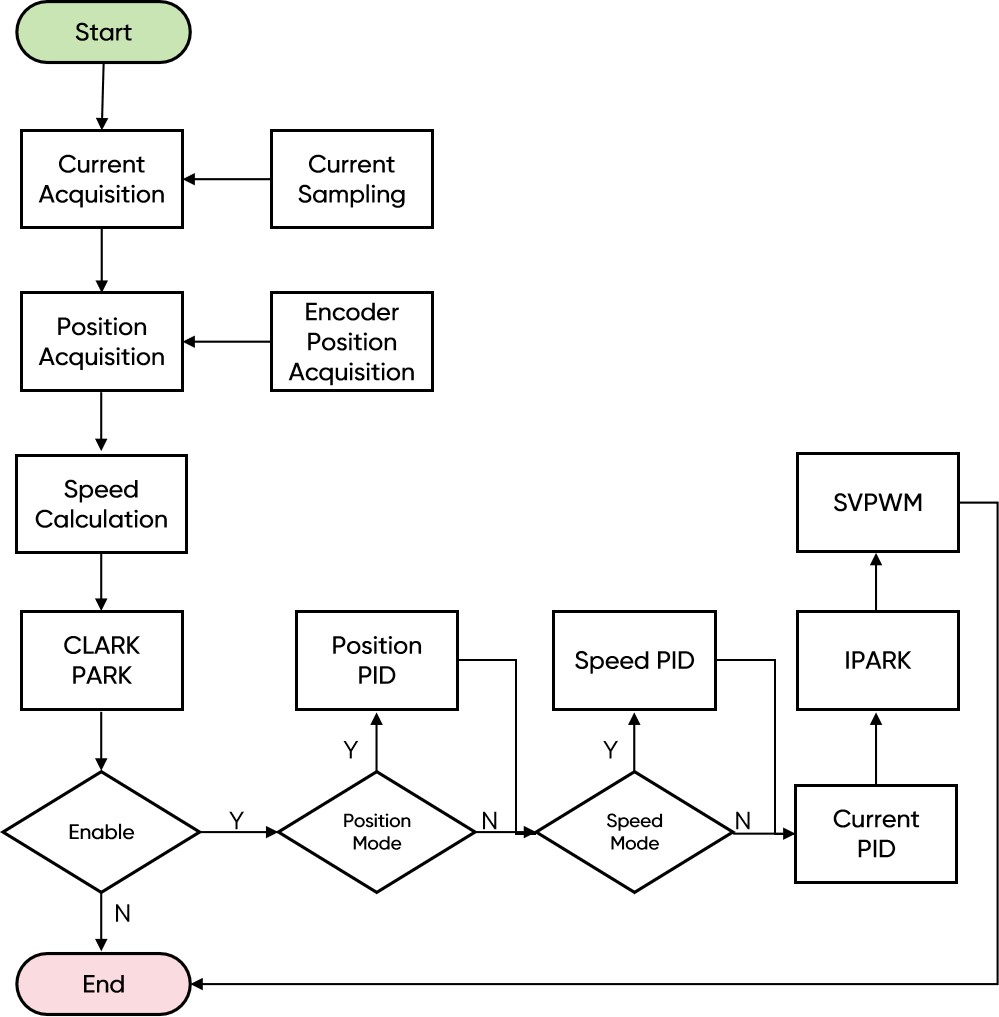

A streamlined single-interrupt architecture implements the full three-loop motor control, enabling users to expand features and achieve higher performance.

Interrupt Processing Flow

Test Data

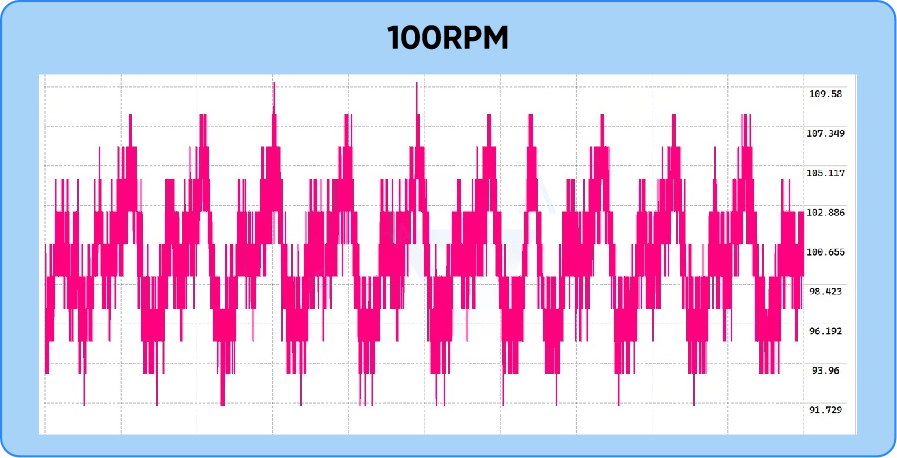

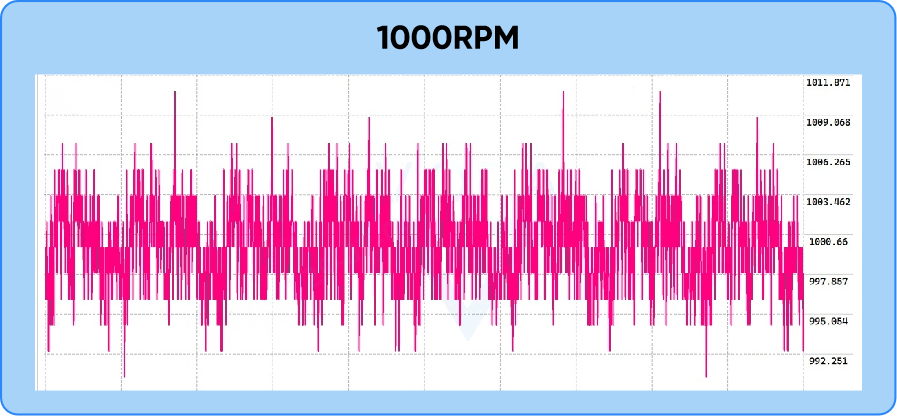

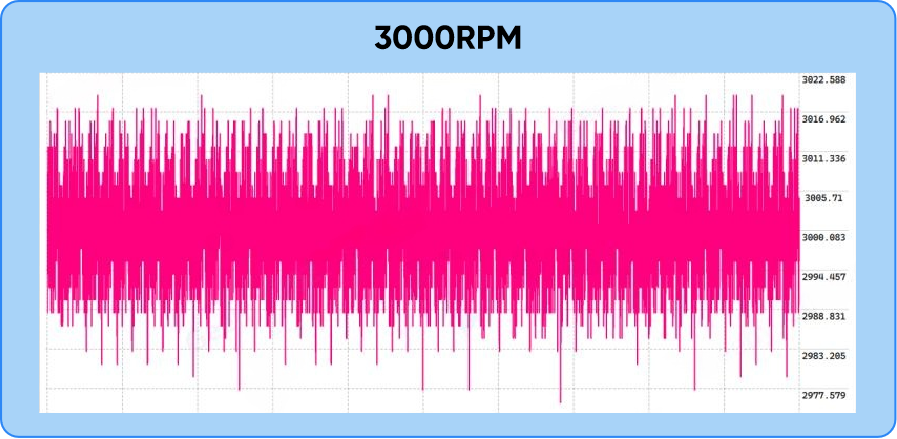

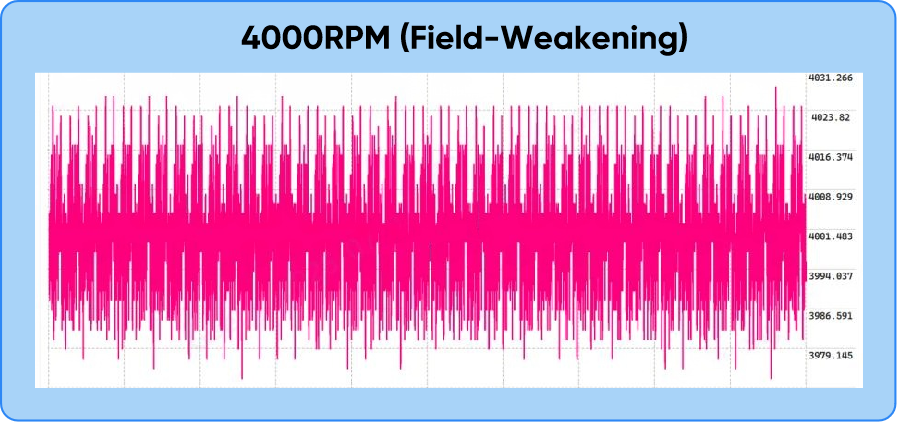

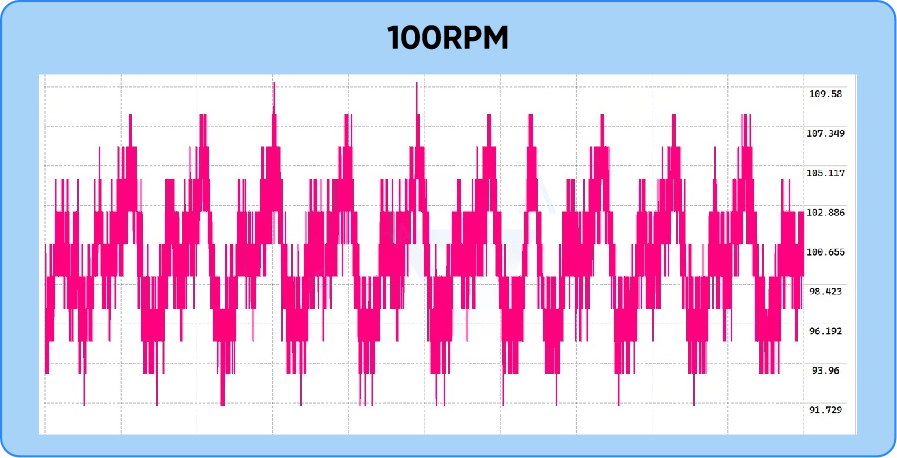

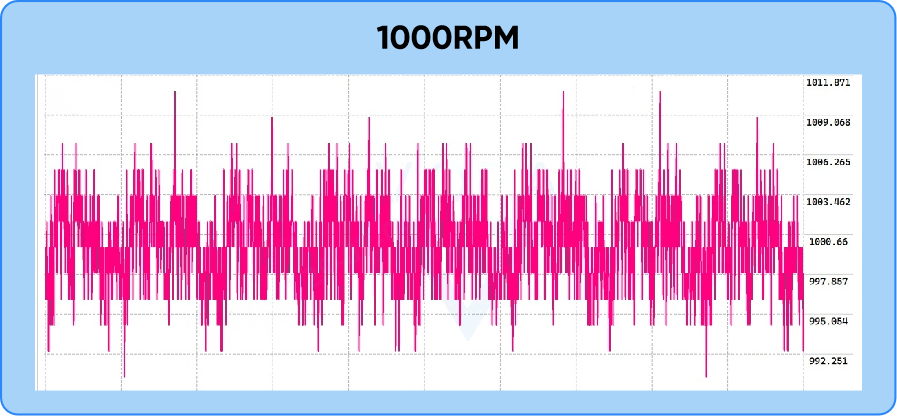

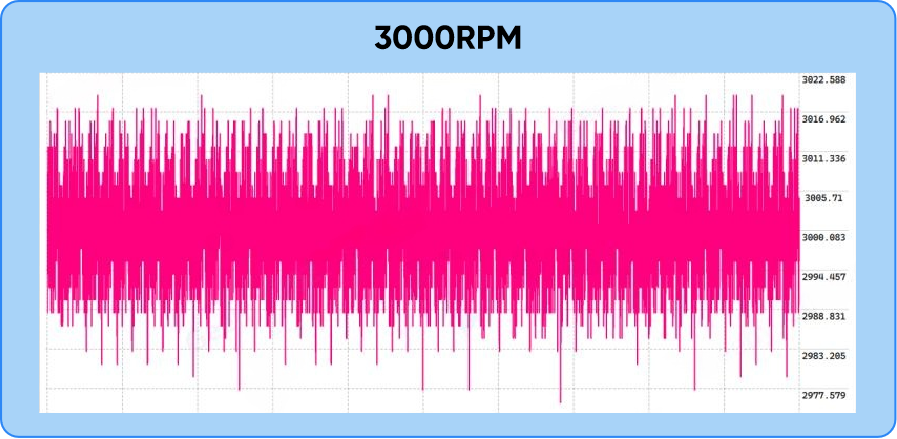

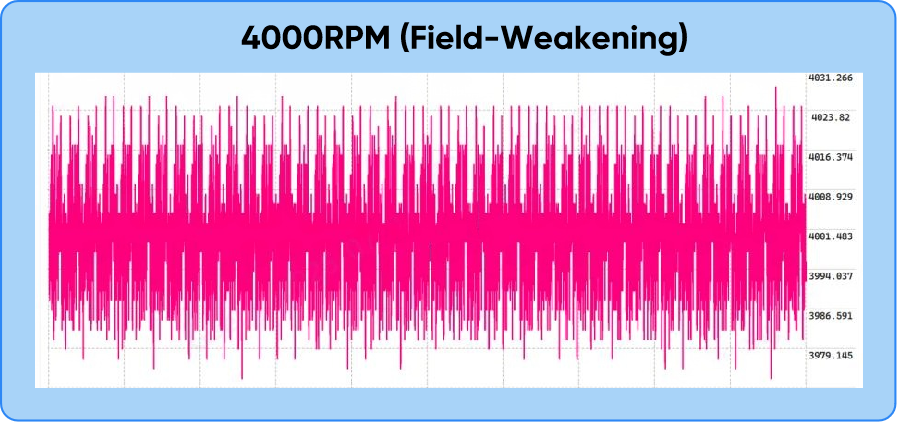

· Speed Ripple Test

Waveforms were collected using a 17-bit magnetic encoder across multiple speed ranges.

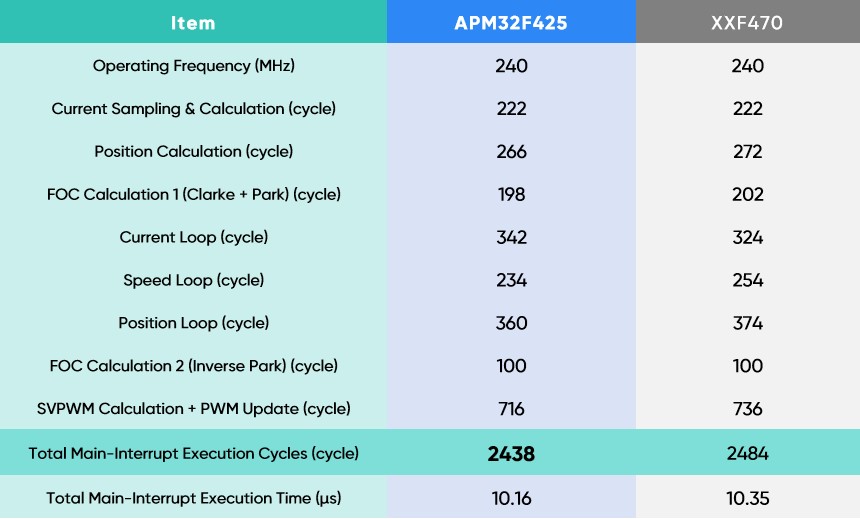

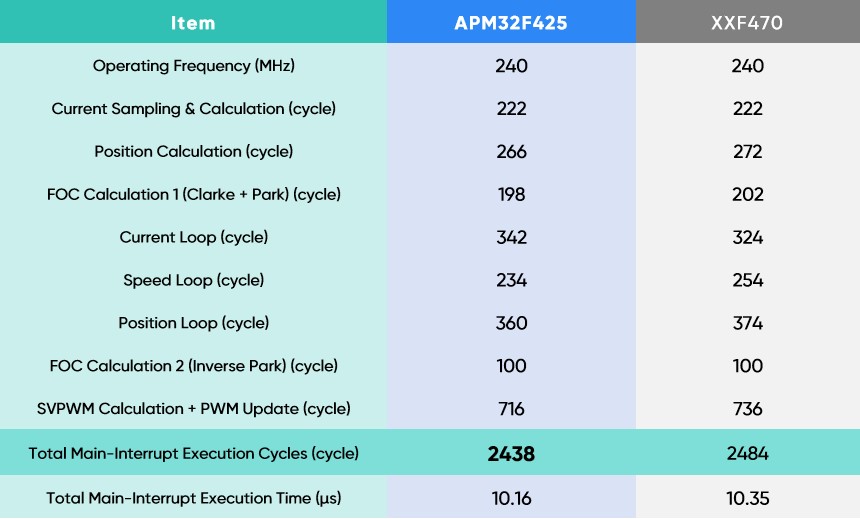

· Execution Efficiency Test

With zero-wait-state operation, APM32F425 delivers strong execution efficiency compared with similar devices.

The APM32F425/427 bus-type low-voltage servo solution provides a complete hardware–software package, including full-function firmware and Geehy's self-developed servo control host tool. Comprehensive documentation is provided for quick deployment, performance validation, and secondary development. All supporting materials are available at Geehy's official website (geehy.com). For more information, please contact your local Geehy sales representative.